Warehouse workers know the feeling: you’re deep in an aisle, mid-task, and the lights suddenly extinguish. Or you turn into a darkened corridor and have to walk twenty feet before the sensors finally wake up. These aren’t isolated glitches from faulty equipment. They are symptoms of a fundamental mismatch between standard motion sensors and the unique geometry of a warehouse aisle.

Most motion detectors are designed for open spaces like offices, where people move in unpredictable patterns. But warehouse aisles are different. They are long, narrow corridors with directional traffic and towering racks that create blind spots. Applying office-grade sensing strategies here creates daily frustrations and genuine safety risks, especially when forklifts and pedestrians operate in the same poorly lit zones. A worker waving their arms to trigger a light is a system that has failed, becoming an obstacle rather than an aid.

Solving this problem requires moving beyond generic hardware. It demands a deliberate design approach that accounts for long sightlines, cross-aisle interference, and the constant vibration from heavy equipment. The goal is predictable, reliable lighting that supports workflow, not interrupts it.

Why Warehouse Aisles Defeat Standard Motion Sensing

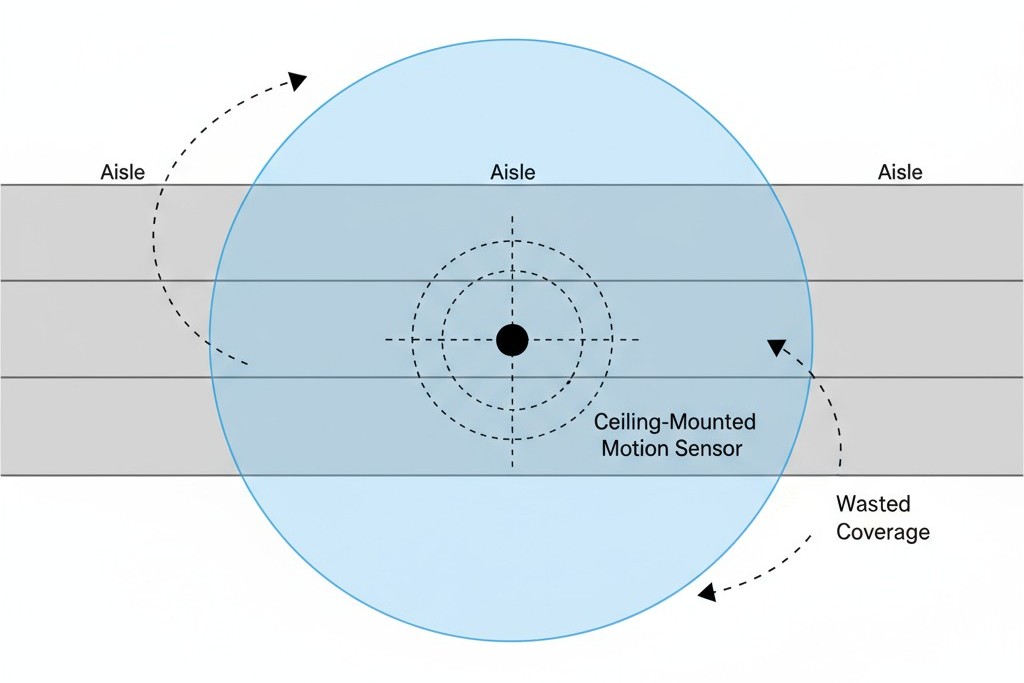

Motion sensors built for commercial spaces assume an open floor plan with moderate ceiling heights, where people can approach from any direction. A ceiling-mounted sensor in an office, for example, expects to detect someone walking across its field of view, a movement that creates a clear thermal signal. It’s optimized for omnidirectional coverage in a square or circular area.

Warehouse aisles violate every one of these assumptions. The geometry is linear, not radial. An aisle might be a hundred feet long but only ten feet wide—an extreme aspect ratio that no single sensor can cover efficiently. People don’t cross the space at various angles; they move straight down the aisle, either toward the sensor or away from it. This head-on movement is notoriously difficult for passive infrared (PIR) sensors to detect because it generates minimal lateral motion across the sensor’s detection zones.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

This mismatch becomes obvious when a worker enters from the far end of an aisle. They can advance dozens of feet into the darkness before the sensor finally registers their presence, creating a clear safety hazard. The tempting fix—cranking up the sensitivity—often backfires. An overly sensitive sensor may trigger from activity in an adjacent aisle or from vibrations in the racking, leaving lights on in empty spaces and wiping out any energy savings.

The physical barriers of the aisle compound the problem. Tall racks loaded with pallets form solid walls, blocking a sensor’s line of sight into perpendicular aisles. A worker at an intersection can be completely invisible to a sensor in the next aisle over, meaning they can turn a corner and step directly into darkness. This isn’t a sensor defect; it’s the predictable result of using technology designed for open sightlines in an environment defined by obstructions.

Finally, standard sensors assume stable mounting conditions. Office ceilings are rigid and vibration-free. Warehouse structures, however, hum with mechanical stress from speeding forklifts and dropped pallets. When sensors are mounted to racking, this vibration can shift their alignment, cause calibration to drift, or even trigger false alarms. The result is unreliable coverage that either fails to detect people or wastes energy on false positives. These aren’t edge cases; they are the defining characteristics of the warehouse environment.

Aisleway Optics and The Long Sightline Challenge

The optical challenge in an aisle starts with a sensor’s field of view. A passive infrared sensor works by detecting a warm object moving between its segmented detection zones. Movement across these zones creates a strong signal. Movement toward the sensor, however, can keep an object within a single zone for too long, producing a signal too weak to trigger the lights.

Warehouse aisles force this worst-case scenario. Because most movement is linear, a worker walking toward a sensor at the end of the aisle is moving in the least detectable way possible. The sensor may have a clear line of sight, but that isn’t the same as reliable detection. This is why ultrasonic or microwave technologies, which detect Doppler shifts from approaching motion, are often considered for aisles, despite their higher cost and sensitivity to interference.

Detection Cone Geometry in Narrow Corridors

Aisle width further constrains the options. A standard sensor might project a detection cone covering a 20-foot radius on the floor—perfect for an open area. In an 8-foot-wide aisle, however, most of that coverage spills into adjacent aisles. The sensor can’t narrow its view to match the aisle without sacrificing its detection range down the length.

Mounting height adds another layer of complexity. Higher mounting extends the sensor’s range but flattens its viewing angle, making it even harder to detect approaching motion. Lower mounting improves sensitivity but shrinks the coverage area, requiring more sensors per aisle. The ideal height is a careful calculation based on the sensor’s pattern, aisle width, and expected traffic—a calculation rarely provided in data sheets designed for open-plan offices.

In a 100-foot aisle, a sensor must perform reliably at its maximum range, where the signal is weakest. Environmental factors like temperature stratification, common in tall warehouses, can create thermal layers that interfere with infrared detection over long distances. A sensor that works perfectly in a climate-controlled office may falter where the floor-to-ceiling temperature difference exceeds 15°F.

The Directionality Problem for Linear Traffic

The predictable, one-way traffic in aisles presents another challenge. If a worker walks down an aisle and pauses to retrieve an item, all motion stops. A sensor relying on continuous movement will immediately start its timeout countdown. If the timeout is too short, the lights go out while the worker is still there, forcing them to wave their arms to turn them back on.

Dual-technology sensors, which combine passive infrared with ultrasonic or microwave detection, can help by maintaining presence detection even when motion ceases. The ultrasonic component can detect the small movements of a person standing still. However, these sensors must be carefully tuned to avoid false triggers from forklifts passing in the next aisle, which can create pressure changes mistaken for occupancy.

Often, the best solution is strategic placement. Mounting sensors at both ends of a long aisle transforms a single long-range problem into two more reliable, shorter-range tasks. While this increases equipment cost, it addresses the fundamental geometric challenge that a single sensor cannot overcome.

Cross-Aisle Masking and Coverage Gaps

The most disruptive failure in aisle lighting is the blind spot at an intersection. A worker standing at a T-junction is visible to sensors in their current aisle but completely hidden from sensors in the perpendicular one. When they turn the corner, they step into a space where the lighting control system has no idea they exist. The lights stay off until the worker walks far enough to trigger a sensor, if one is even positioned to see them.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

The cause is simple: racking creates a solid wall that blocks a sensor’s view. A sensor in Aisle A cannot see around the corner into Aisle B. No amount of sensitivity can fix this. The only solution is to position sensors to ensure every possible entry point into an aisle is monitored by a device with a direct line of sight.

This directly conflicts with the goal of minimizing sensor count. A design using the fewest possible sensors—placing one in the middle of each aisle—will inevitably fail at intersections. The worker entering from a cross-aisle becomes a ghost to the system, present but undetected. This failure erodes trust and leads to unsafe workarounds, like propping doors open for ambient light or disabling the motion controls entirely.

Designing for Intersections and Zone Handoffs

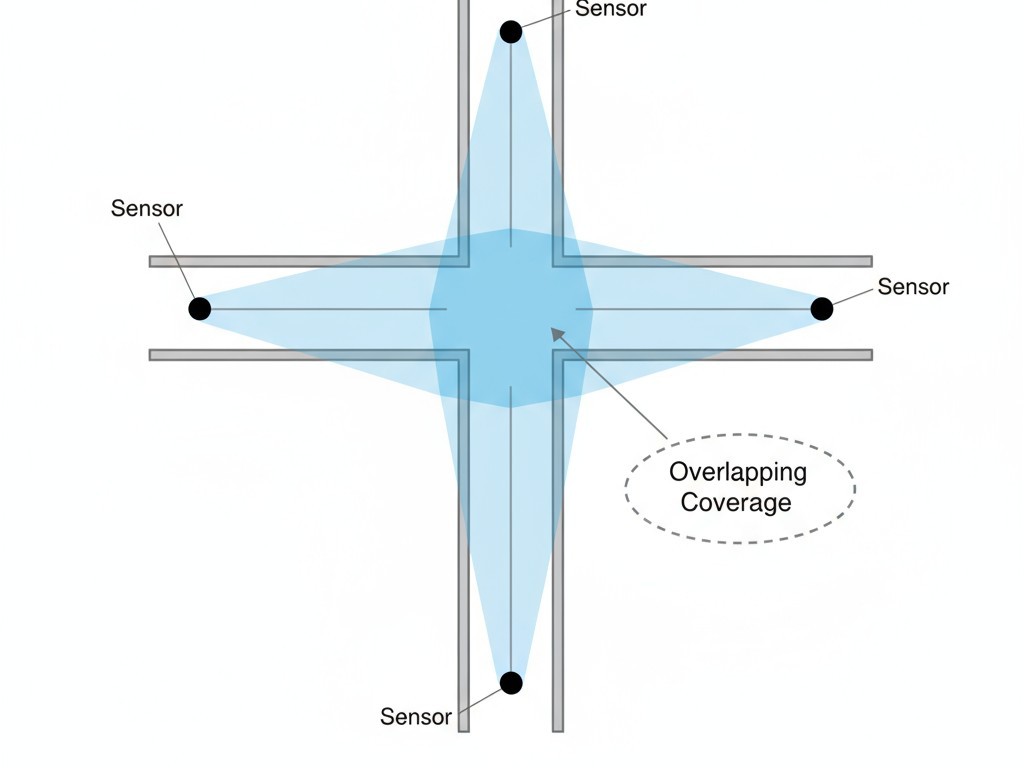

The solution is to treat intersections as distinct zones requiring dedicated sensors. Instead of relying on a mid-aisle sensor, place sensors at the intersection itself, oriented to monitor entry from all connecting paths.

The handoff between these zones is critical. As a worker moves from Aisle A to Aisle B, the lights in Aisle A must stay on until they are fully inside the detection zone for Aisle B. A gap between the two zones creates a momentary blackout at a hazardous transition point. This is managed by overlapping the detection zones by five to ten feet, creating a seamless buffer.

Intersection timeouts can also be configured differently. Since these are transition points, not work areas, a shorter timeout of 30 to 60 seconds is often sufficient. This saves energy without interrupting tasks, as long as it doesn’t conflict with the longer timeouts needed for the main aisles where stationary work occurs.

Vibration Challenges from Forklifts and Racking

Warehouses subject sensors to constant mechanical stress. Vibration from forklifts and material handling equipment propagates through the building structure and can interfere with sensor accuracy.

While passive infrared sensors are relatively resistant, severe vibration can gradually shift their optical components, altering the coverage pattern over time. Ultrasonic and microwave sensors are more vulnerable. The vibration of the sensor housing itself can create false Doppler shifts, tricking the sensor into thinking there’s motion. A sensor mounted to a racking beam directly above a forklift’s path may trigger constantly from vibration alone.

The best defense is isolation. Whenever possible, mount sensors to the building’s main structure, not to the racking. If that’s not an option, use vibration-damping hardware—like rubber or elastomeric bushings—to absorb the mechanical energy. For industrial environments, always select sensors with a high vibration tolerance rating, typically expressed in g-forces. A sensor rated for 2g of vibration up to 150 Hz is a good starting point for most warehouse applications.

Timeout Strategies That Respect Task Flow

A sensor’s timeout period—how long the lights stay on after motion stops—has a massive impact on usability. Too short, and workers are constantly interrupted. Too long, and energy is wasted. The optimal timeout must be aligned with the actual work being done.

A 30-second timeout might look good on an energy audit, but it’s disruptive in practice. A worker pausing to find an SKU, scan a barcode, or check a handheld device can easily exceed that limit. When the lights go out mid-task, they have to stop what they’re doing to reactivate them. This context-switching kills productivity. Short timeouts treat every pause as a vacancy, ignoring that aisles are task areas where stationary work is normal.

A better strategy is to set hold times based on the expected duration of common tasks. If a typical picking job takes three to five minutes, the sensor timeout should be at least five minutes. The small energy cost of the lights staying on for an extra minute after a worker leaves is trivial compared to the productivity lost from constant interruptions. Workers learn to trust a predictable system, allowing them to focus on their job.

Configuring Hold Time for Aisle Depth and Task Duration

A good starting point for calculating timeout is to divide the aisle length by the average walking speed, then add the expected duration of the longest common task. For a 100-foot aisle traversed at 3 feet per second (33 seconds), where tasks take up to 4 minutes, the minimum timeout should be around 5 minutes. This ensures continuous light from entry to task completion.

Maybe You Are Interested In

It’s also a myth that shorter timeouts always save more energy. In systems with frequent reactivation cycles, the energy used to repeatedly start lamps can exceed the savings from reduced on-time. This is especially true for older high-intensity discharge lamps, but the productivity cost remains even with LEDs. The best timeout minimizes total cost, which includes both energy and the labor cost of interruptions. In most warehouses, this calculation favors longer, more predictable timeouts.

Sensor Placement and Zone Shaping Principles

Effective sensor placement is a synthesis of all these challenges. The goal is not to maximize the range of each sensor, but to build a reliable detection architecture that workers trust.

The guiding principle is simple: every entry point to an aisle must be monitored by a sensor with a direct line of sight. For a basic aisle, this means placing sensors near each end, aimed to detect approaching traffic. Their detection zones should extend slightly beyond the aisle’s entrance to activate the lights before a worker enters. For aisles with intersections, additional sensors are required to cover all approach directions, with overlapping zones to ensure a seamless handoff.

The sensor’s detection pattern should be shaped to match the aisle’s geometry. Use sensors designed for corridors or those with adjustable patterns to focus detection down the length of the aisle while minimizing spill into adjacent areas. Mounting height should be chosen to balance range and sensitivity, while accounting for vibration and potential obstructions.

Ultimately, the safety implications of these decisions are paramount. A blind spot is not an inconvenience; it is a hazard. A worker stepping into a dark aisle is invisible to an approaching forklift, creating exactly the kind of collision risk that a lighting control system should prevent. The true measure of an aisle lighting design is not its theoretical energy savings, but its ability to provide comprehensive, reliable coverage that eliminates dark zones entirely.