You know the call. It usually comes in on a Monday morning from a frantic restaurant manager or a facility safety officer. The story is always the same: The chef walked into the freezer carrying a full stock pot, the heavy PVC strip curtains swung shut behind him, and three seconds later, the lights went out. He’s standing in pitch black, -10°F air, balancing five gallons of hot liquid, screaming for someone to open the door.

The immediate reaction from the facility team is to blame the sensor. They assume it’s defective, the sensitivity dial got bumped, or it needs a fresh battery. But if you put a meter on it, you’ll find the sensor is doing exactly what it was designed to do. The component isn’t broken. The physics are just misunderstood. This happens in about half of all commercial retrofits: you have installed a device that relies on heat signatures behind a barrier designed specifically to stop heat transfer.

Physics vs. The Brochure

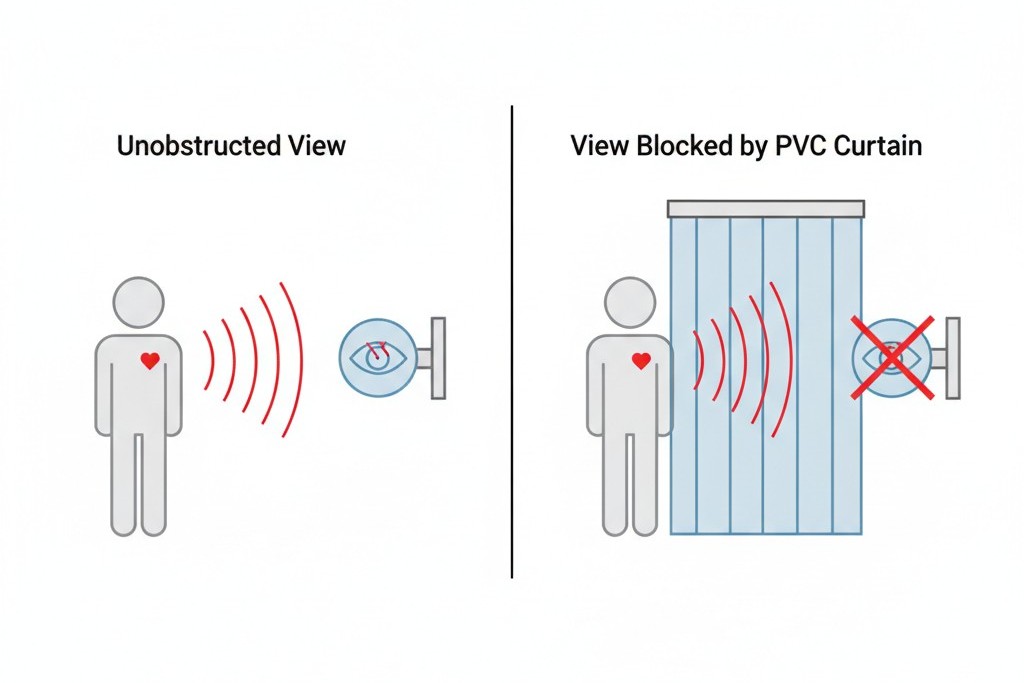

To understand why standard sensors fail here, ignore marketing terms like “occupancy detection” or “wide-angle lens.” Look at the mechanism. The vast majority of lighting controls in walk-ins use Passive Infrared (PIR) technology. Inside that white plastic dome is a pyroelectric sensor that detects changes in infrared radiation—essentially, heat moving across a grid.

When a human body enters a room, the sensor sees a spike in IR energy against the background temperature. But a walk-in cooler or freezer is built to be a thermal fortress. Those thick, ribbed PVC strip curtains (often low-temp polar grade) are excellent insulators. That is their entire job.

Here is the hard reality: To a PIR sensor, clear PVC is not a window. It is a brick wall.

You can see through it because visible light passes through the polymer chains. But infrared radiation, which has a longer wavelength, gets absorbed or reflected by the material. When the curtain closes, the thermal signature of the person inside is effectively erased. The sensor sees the cold surface of the plastic, sees no heat movement, and assumes the room is empty. It cuts the circuit. It doesn’t matter if you buy the expensive Wattstopper FS-series or a generic knockoff; if it relies on PIR, it cannot see through a thermal barrier.

Maybe You Are Interested In

There is some nuance—very thin, high-temp strips might leak a ghostly amount of signal, or a gap might let a sliver of heat through. But relying on that leakage for safety is a negligence lawsuit waiting to happen. If you are speccing a job, assume the attenuation is 100%.

The Geometry Fix (The Inside Job)

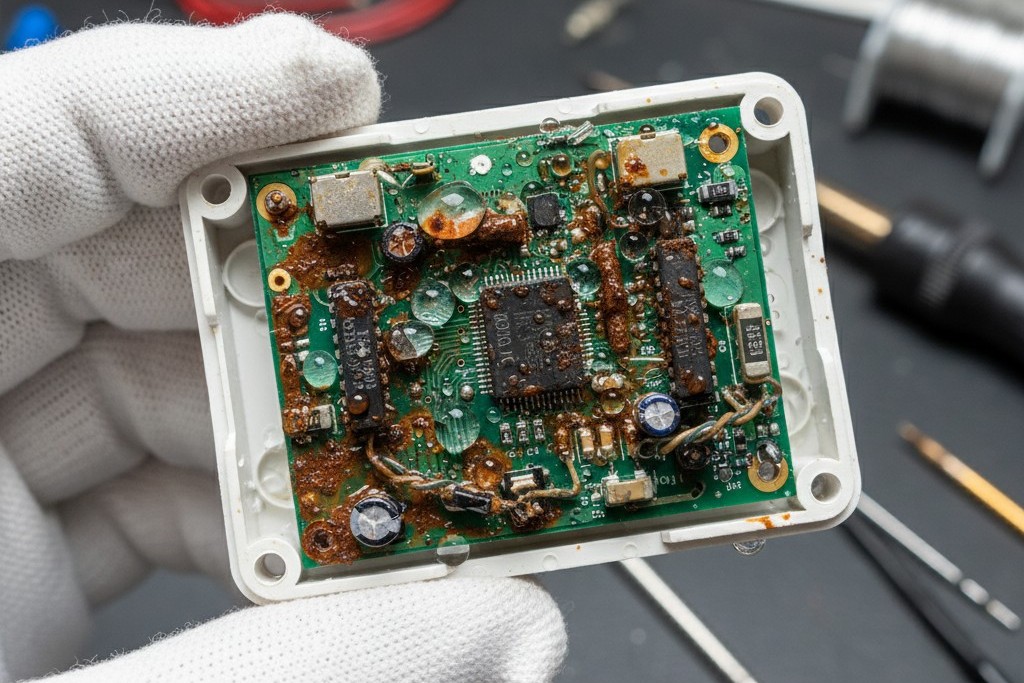

If the strip curtain is the wall, the sensor has to live on the other side of it. This sounds obvious, but moving a sensor from the warm side (outside the box) to the cold side (inside the box) introduces a new set of enemies: condensation and ice.

The standard move is to mount the sensor on the interior ceiling, well past the curtain line. But you cannot just slap a standard junction box up there and walk away. When warm, humid air from the kitchen sneaks into the conduit, it travels down the pipe until it hits the cold air inside the freezer box. That moisture condenses instantly. If your sensor is the low point in that conduit run, it will fill with water. I have opened plenty of “failed” sensors only to pour out half a cup of rusty water that shorted the PCB.

If you move the sensor inside, you must use a sealed, NEMA 4X rated enclosure. More importantly, you have to seal the conduit entry. A glob of silicone or a proper conduit seal fitting prevents that warm kitchen air from migrating into the device.

Once the hardware is hardened, you have to aim it. A ceiling mount in the center of the aisle is standard, but consider the “Gap Hack.” In high-traffic distribution centers where forklifts are moving fast, we often mount the sensor high up, aiming it specifically at the gap where the curtain rail meets the wall. Even the best-hung curtains usually have a 2-inch thermal leak at the top. By aiming the detection lobes at that specific leak, you can sometimes trigger the lights before the forklift fully breaches the curtain, buying the driver those crucial milliseconds of illumination.

The Mechanical Override

Sometimes, the best sensor is no sensor at all. In the rush to make everything “smart,” we often forget that a physical switch is the most reliable indicator of occupancy. If the door is open, someone is entering or leaving.

The most bulletproof solution for a walk-in with heavy curtains is to bypass the motion requirement entirely using the door itself. This involves installing a magnetic contact switch on the door frame—think of a standard alarm contact, but industrial grade (like the Sentrol 2500 series).

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

The logic is simple: When the door opens, the magnet breaks the circuit. A relay in your lighting controller sees this state change and latches the lights ON for a set period (say, 15 minutes). It doesn’t matter if the person is hidden behind three layers of ribbed PVC or standing perfectly still counting inventory. The system knows the door was cycled, so it assumes occupancy.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

This approach does have a weakness: the “Magnet Tape” hack. Staff, frustrated by alarms or auto-closers, will sometimes tape a spare magnet to the sensor to trick the system into thinking the door is closed so they can prop it open for deliveries. If your lighting logic is tied solely to “Door Open,” this trick will plunge them into darkness. The fix is to use the door switch as a trigger to start a timer, not as a momentary contact.

The False Prophets: Ultrasonic and Wireless

In the search for a workaround, you’ll hear people suggest Ultrasonic or “Dual-Tech” sensors. The theory is sound: Ultrasonic sensors use sound waves (Doppler shift) instead of heat. Sound waves go through gaps and bounce around corners, filling the volume. They can “hear” a person behind a curtain.

But in a commercial freezer, this is a trap. The environment inside a walk-in is hostile to ultrasonics. The massive evaporator fans (think big Bohn or Kramer units) create constant air turbulence and vibration. To an ultrasonic sensor, that vibrating fan blade looks like motion. You end up with the opposite problem: the lights never turn off. You can try to dial down the sensitivity, but then you risk missing the guy standing still in the corner. Unless you have a very quiet, low-velocity box, avoid ultrasonics.

The other trap is wireless retrofits. Vendors love to sell battery-operated “peel and stick” sensors to save on conduit labor. Do not do this in a freezer. Lithium batteries have a steep voltage drop-off in sub-zero temperatures. A battery rated for 2 years in a hallway will last about 3 months at -10°F. You are trading a day of conduit labor for a lifetime of callback tickets to change batteries.

Final Calculations

This is risk management, not just wiring. If a sensor fails to turn on in an office, someone waves their arms and gets annoyed. If it fails in a walk-in freezer, someone can get hurt, or a health inspector can write up a violation for inadequate lighting.

Don’t let the general contractor bully you into mounting the sensor above the door on the outside “because it’s easier.” Explain the thermal blocking. Explain the physics. If they insist on the cheap way, put it in writing that the system will not function when the curtains are hung. Then, get your conduit bender, seal your penetrations, and put the eye where it can actually see.