Occupancy sensors are widely used in residential, commercial, and IoT applications for lighting automation and energy-saving purpose. They are one specific kind of motion sensor that detects whether a space is occupied or not by a person.

This comprehensive guide includes everything you need to know about occupancy sensors, what they are, how they work, common types, and their advantages to help you determine the best occupancy sensor solutions for your home and offices.

Contents

- What Is an Occupancy Sensor

- How Do Occupancy Sensors Work

- Occupancy Sensor Types

- Types of Occupancy Sensors by Mounting

- Types of Occupancy Sensors by Power Supply

- Occupancy Sensor Features

- Why Use an Occupancy Sensor

- Occupancy Sensor in IoT

- Occupancy Sensor vs. Motion Sensor

What Is an Occupancy Sensor

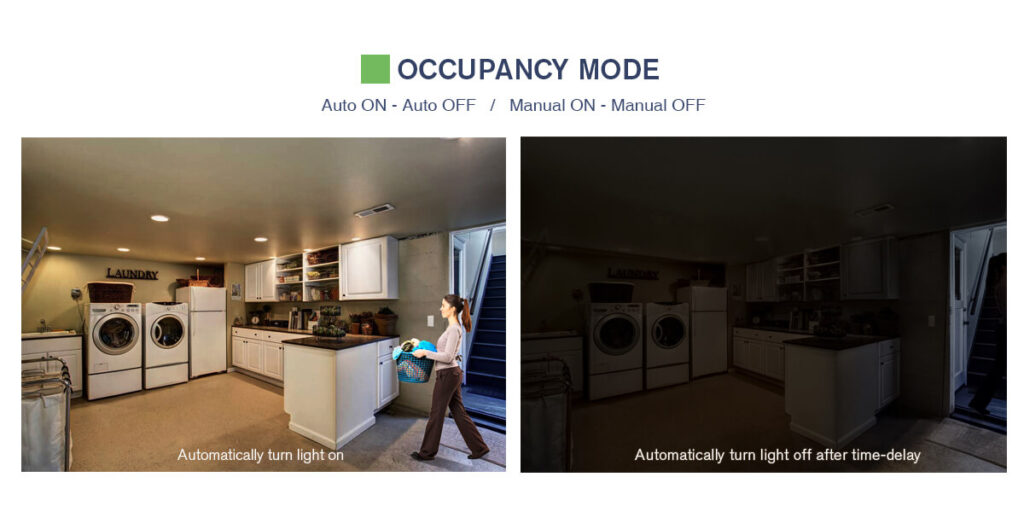

An occupancy sensor is a kind of motion sensor that detects the presence of a person in the detecting area. They are commonly referred to as auto-on, auto-off sensors. For example, when used to control lights, the occupancy sensor turns on the light when the sensor detects a person walking in the room and keeps the light on while the person is staying. The sensor will turn off the light automatically after the person leaves and has not returned to the room after some time(time delay). The principles are the same when an occupancy sensor is used in other applications. An example is the exhaust fans in public restrooms that automatically turns on when you need to use the bathroom and off after you leave.

Occupancy sensors and their solutions are widely used in residential and commercial buildings to automate lighting and ventilation systems like fans and HAVC to reduce energy waste and create a hands-free, convenient living and working environment.

In commercial buildings, occupancy sensors are commonly required by energy codes to meet the energy-efficiency standard. They are also widely used in Internet of Things(IoT) networks to help monitor and analyze the data to improve room efficiency and space utilization.

Vacancy Sensor

A manual-on, auto-off occupancy sensor is commonly called a vacancy sensor because it detects the vacancy status of the room. A vacancy sensor requires the user to manually turn on the light, and it will shut off the light automatically after the person leaves. Thus the name manual-on and auto-off occupancy sensor.

Compared to occupancy sensors, vacancy sensors are more energy-efficient because the light can only be turned on by actual users, not by the sensor in any way. An occupancy sensor may detect a person passing by the room and turn on the light in an empty room. This is known as a false-on which is an obvious waste of energy. Vacancy sensors can effectively prevent false-on from happening. Given this, most energy code specifically requires vacancy sensors to be used in various places in commercial buildings.

A 15-30 second vacancy confirmation window time is added after the time delay so that the vacancy sensor can still be activated by motion singles during this time period. After the confirmation time expires, users have to manually switch on the light.

Occupancy Vacancy sensor

Some occupancy sensors will integrate both occupancy and vacancy mode to meet various use cases, so users don’t need to replace or install another sensor when they want to change the motion detection mode. This kind of sensor is usually called an occupancy/vacancy sensor or occupancy sensor for short. Most occupancy/vacancy sensors are sensor switches so that users can buy the same type of light sensor switch for every room and then adjust the working mode for each individual room.

However, most sensors are single mode, either occupancy or vacancy sensor, that can only work in one motion detection mode. For most residential and commercial applications, you don’t need to change the mode from occupancy to vacancy or vice versa after the sensor is properly installed.

How Do Occupancy Sensors Work

How occupancy sensors detect motion and the presence of people is mainly based on the sensor technology it utilizes. There are various sensors and sensing technologies, but the most common sensing technologies used in occupancy sensors are PIR, ultrasonic, microwave, and dual technology.

Each technology has its pros and cons, and they each have specific methods for motion detection. Knowing their mechanics and how they detect motion singles can help you to choose the ideal sensor type for your projects.

PIR Sensors

Passive infrared sensors, or PIR sensors, detect the infrared emitted by people to tell whether they are in motion or not. PIR sensors use two pyroelectric sensors, which are sensitive to infrared signals to detect the infrared radiation in the environment. When there is no movement in the background, the PIR sensor should detect the same IR amount in both two pyroelectric sensors(slots).

When a warm body, i.e., a person or a cat, walks into the detecting space, it first intercepts one slot and then the other slot of the PIR sensor, which causes a positive differential change between the two IR signals. PIR sensors see this change as a sign of motion, so they know the room is now occupied. When the person leaves, the reverse happens, the PIR sensors know the room is now empty and unoccupied.

Based on how it detects motion, we know that a PIR sensor is more sensitive to people walking across the sensor(lateral motion) but less sensitive to people walking towards or away from it(axial motion). This characteristic is vital when installing and adjusting occupancy sensors to get the best performance.

PIR motion sensors are more sensitive to significant and large movements like walking up to about 40 feet(12 m). They have limited sensitivity to minor movements like typing at a distance greater than 15 feet(4.5 m).

The term passive means PIR sensors are passively detecting heat signals emitted or reflected in the background. It does not send out detecting signals like an ultrasonic sensor, making the PIR sensor very energy efficient and using only a little power to function. It also distinguishes a PIR sensor from an active IR sensor.

Pros and Cons

Being the most basic but also the most commonly used sensors in both occupancy sensors and other motion detector applications, PIR sensors do have very competitive advantages.

PIR sensors are very inexpensive, durable, and energy efficient. They only need very little power to function, making them the ideal sensor solution for long-term applications.

Another reason why PIR sensors are suitable for occupancy sensors is that occupancy sensors and PIR sensors all mainly detect people’s presence. Motions that PIR sensors are able to detect are mostly from warm bodies, which can rule out many non-human activities. This also makes PIR sensors suitable for spaces with high airflow where ultrasonic sensors are not competent in such applications. On the contrary, PIR sensors cannot be installed near distraction sources where heat changes rapidly, such as HVAC and coffee machines which can be detected as a false motion signal.

Because infrared signals cannot move past walls or obstacles, PIR sensors require a clear line of sight from the detecting area, meaning PIR sensors must be able to “see” the motion. They can not see through obstacles, glasses, or corners to detect infrared signals. This can be both a pro and a con.

The con is that PIR sensors are only good for small to medium enclosed spaces with a clear line of sight. Places such as public restrooms with many stalls are not a place to install PIR occupancy sensors.

The pro is that you are able to adjust the detection range to monitor only a selective area of space. By masking part of the lens on the sensor with adhesive tapes, you can restrict its detection coverage, preventing the sensor from detecting certain areas. If your PIR occupancy sensor is constantly getting activated by people passing the room, you can mask part of the lens to avoid these false triggers.

Ultrasonic Sensors

Ultrasonic sensors emit high-frequency sound waves above the human hearing range throughout an area to detect motion. Ultrasonic sensors have transducers inside, comprised of a transmitter and a receiver. The

soundwave sent from the transmitter bounces off objects in the area and reflects back to the receiver. If there is a change in the frequency of the reflected sound waves, the change is interpreted as a motion. By measuring the time between sending and receiving the sound wave, ultrasonic sensors can determine the distance between the sensor and the target.

The ultrasonic sensor is an active sensor that needs to continuously send and receive ultrasonic sound waves to detect motion, which means they need to consume a good amount of power for the sensor to function.

Ultrasonic sensors do not require a line of sight, making them ideal for places and applications with obstacles in the path, such as public restrooms with multiple stalls.

Pros and Cons

Ultrasonic sensors are highly suitable for spaces where a line of sight is not possible, such as partitioned spaces such as public restrooms, open offices, enclosed hallways, and stairways. Ultrasonic sensors typically have a larger coverage area at a distance of up to 25 feet.

Ultrasonic sensors are highly sensitive, making them ideal for places with low-motion activity and minor movements or applications where a high level of sensitivity is required, like people typing and turning pages. They are most sensitive to motions to and from the sensor due to the characteristics of ultrasonic sound.

On the contrary, ultrasonic sensors are not good for places with high levels of airflow vibrations because the vibration can trick the sensors into falsely turning on and off. And they are not competent for applications where only a selective range needs to be monitored, such as control of individual warehouse aisles.

Microwave Sensors

Microwave sensors emit low-power electromagnetic radiation and receive the reflected microwave for motion detection. The microwave pulse emitted from the sensor bounces off objects in the room and reflects back to the receiver of the microwave sensor. If the microwave is altered in the reflected microwaves, the change is interpreted as a motion. They can also tell whether the target is moving towards or away from the sensor or randomly in the room by analyzing the waves so that they can also be configured to detect different types of activities.

Microwaves can penetrate walls and holes, which means they have a more extensive detection coverage for both inside and outside usage. Microwave sensors are very versatile and can be used in virtually any environment.

Pros and Cons

Microwave sensors are inexpensive to purchase but costly to run because it needs to constantly draw power to emit and receive microwave. So most microwave sensors work intermittently to reduce costs and are designed to cycle from ON and off status, which may be an obvious pattern. But it can also work constantly in a busy house to reduce on and off circles.

Microwave sensors are extremely sensitive and usually not accurately configured, so they can cause many false triggers or false alarms and are more susceptible to electronic interference.

Dual-Techonolgy Sensors

Dual technology or dual-tech sensors combine PIR and ultrasonic sensing technologies for motion detection. The combined technologies significantly increase the sensor’s overall reliability for complex and high-sensitivity applications.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

In idle mode, only the PIR sensor is working to detect motion, while the ultrasonic sensor is in sleep mode to reduce energy consumption. When the PIR sensor detects a motion, the ultrasonic sensor now wakes up to validate the same motion. Only when both two sensors have detected the same motion the dual-technology sensor is now activated. This design can ensure the lowest possibility of false-on.

As long as either PIR or ultrasonic sensor is continuously detecting motion, the dual-tech sensor is kept activated. When both sensors cannot detect the motion, the dual-tech sensor now thinks the room is empty. This design can lower the possibility of false-off.

Most dual-technology sensors are also self-adaptive to adjust sensitivity and timing automatically.

Passive & Active Sensors

Many people tend to call PIR sensors passive sensors and ultrasonic, microwave, dual-tech and other types of sensor active sensors. This is a personal preference for calling sensors and we also list the type here for our readers.

Typically passive sensors are durable because they don’t use much electronics so they have fewer possibilities of electronic failure. And they use much less power as they only receive signals without the need to emit.

Occupancy Sensor Types

Occupancy sensors can be sorted by different factors, such as sensor technology, install locations, working voltage, etc. To help users choose the most suitable sensor types for their home and commercial application, we will try to cover every major occupancy sensor type and explain their advantages, differences, and usages.

Types of Occupancy Sensors by Mounting

Occupancy Sensor Switch

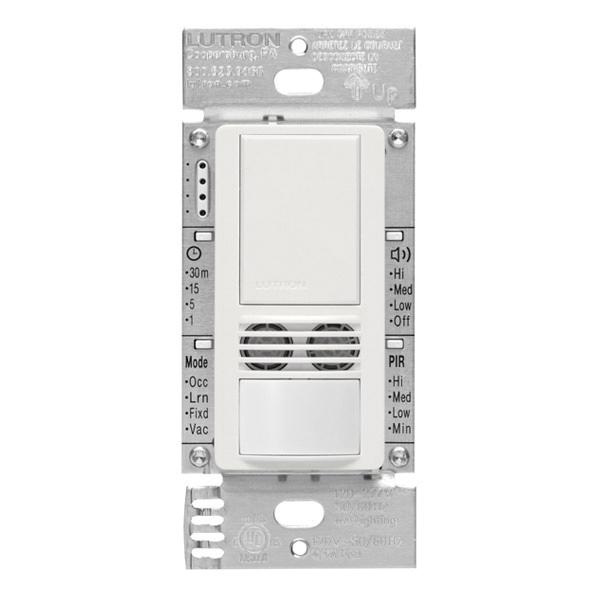

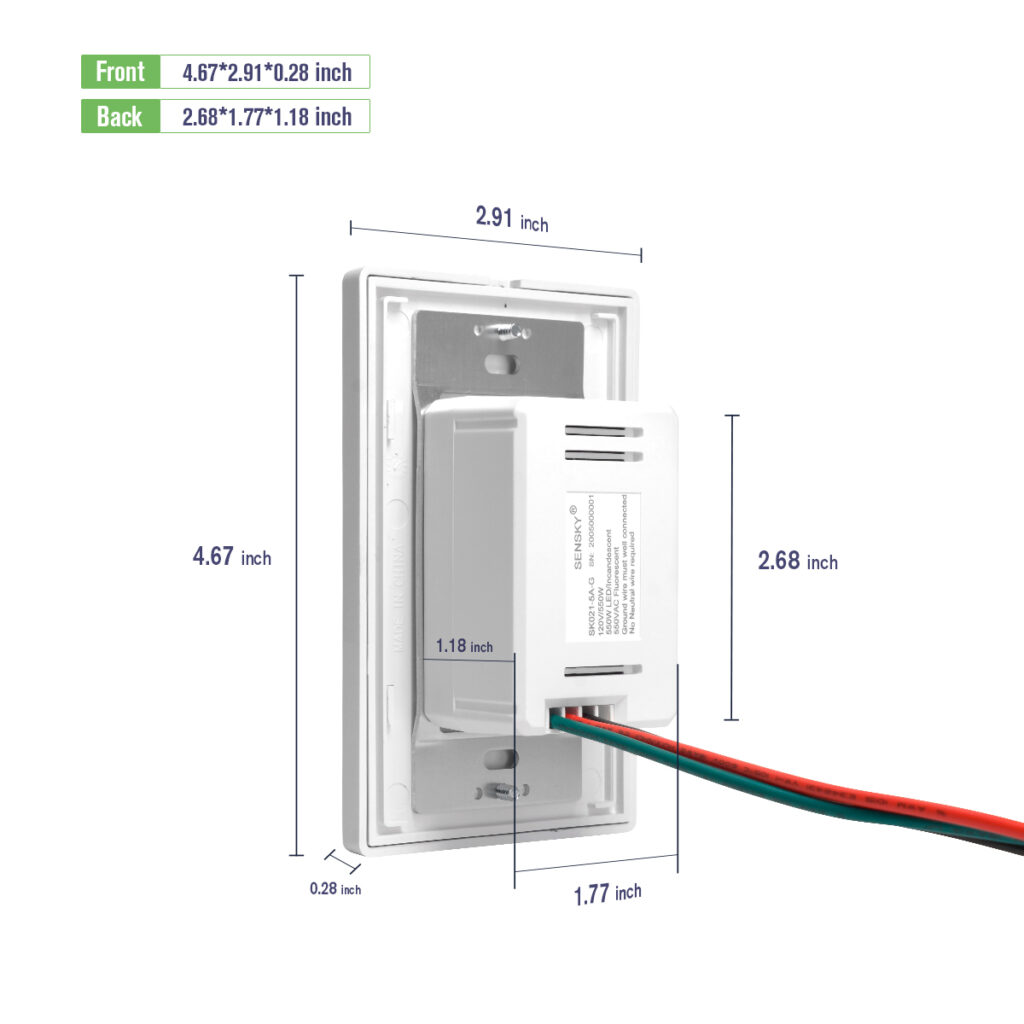

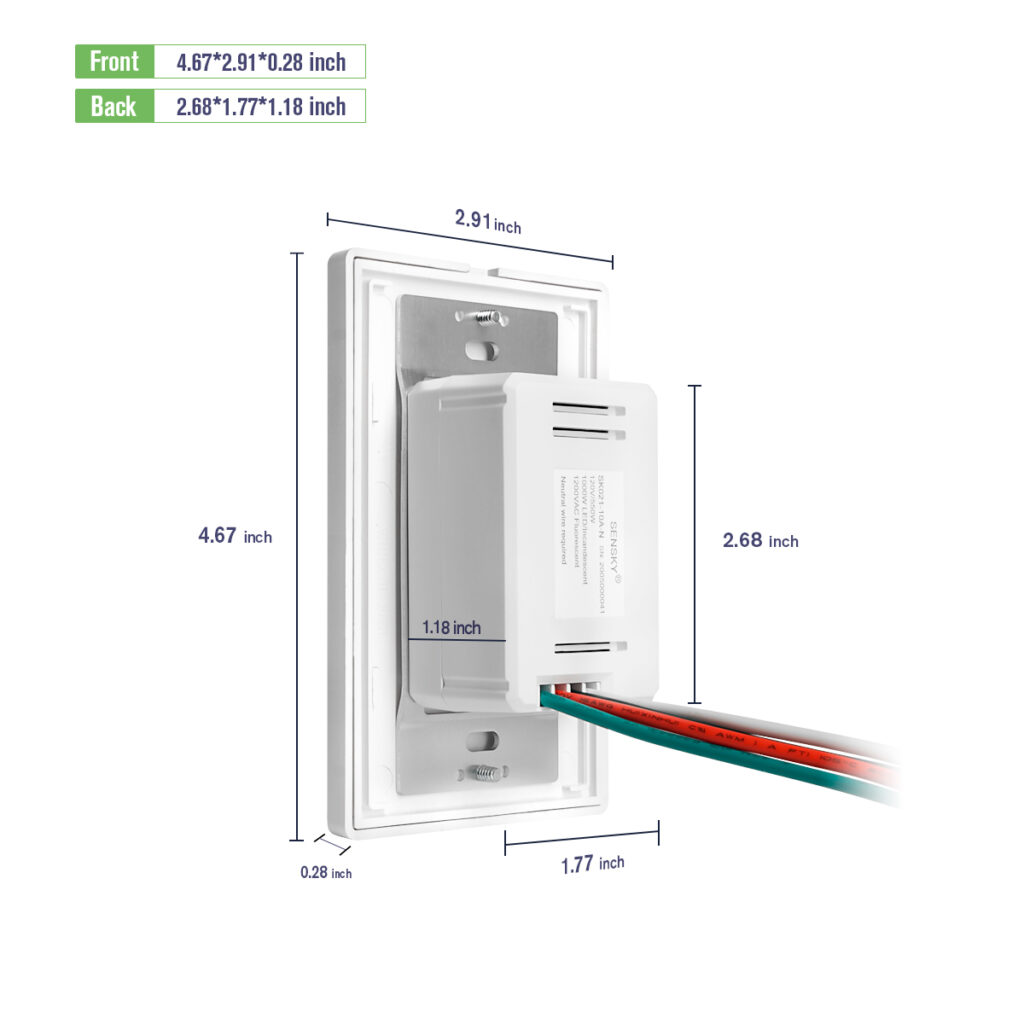

Occupancy sensor switches are switch-type occupancy sensors. They are also called in-wall occupancy sensors, occupancy sensor wall switches, or motion sensor switches.

Unlike other occupancy sensors that are mostly mounted on the surface of the wall or ceiling, occupancy sensor switches are installed in the wall switch box. Most occupancy sensor switches are specifically used to control lighting or fans to replace regular light switches. Because they act more like a light switch with a built-in occupancy sensor feature rather than a standalone occupancy sensor, the wall switch type is more commonly called a motion sensor light switch.

One significant advantage of occupancy sensor switches is that they integrate the control(switch) and sensor into one, so it’s convenient for users to override the sensor and manually control the light. For the same reason, almost all vacancy sensors are switch type sensors as they don’t need to connect to another switch or control to turn on the light. In contrast, most ceiling and wall mount sensors are occupancy sensors only, mainly for detecting the occupied status of the room.

Single-Pole Occupancy Sensor Switch

Single-pole occupancy sensor switches are the standard type of sensor switches and can control one or multiple light fixtures from a single location.

Three-Way Occupancy Sensor Switch

Three-way occupancy sensor switches allow you to control one or multiple lights from two different locations, such as the beginning and end of a long hallway or stairway. What you need are a three-way occupancy sensor switch and a three-way regular light switch, and install the 3-way occupancy sensor switch at either end and the 3-way light switch at the other end.

You cannot use two 3-way occupancy sensor switches at both ends because they will fight for the control of the lights. Only one occupancy sensor switch can be used in 3-way or multi-location installations.

Neutral and Ground Required

When selecting occupancy sensor switches, you need to specifically pay attention to the wiring requirement.

The occupancy sensor switch requires an individual power supply for the sensors to detect motion and activate the relay switch even when the light is turned off. That’s why most occupancy sensor switches require a neutral wire to work. That neutral wire is for the occupancy sensor to draw a bit of standby power continuously. These types of sensor switches are called “neutral required” occupancy sensor switches. Most modern homes now include a neutral wire in the wall switch box, so the neutral wire required occupancy sensor switch can function properly.

If you have a neutral wire in the switch box, you should choose a neutral required occupancy sensor switch. These switches have 4 wires, a load wire, a hot wire, a neutral wire and a ground wire.

Older homes may not have a neutral wire available in the switch box because the national electrical code did not require neutral wires in the switch box at that time. A “ground required” or “no neutral required” occupancy sensor switch is made for this situation. Instead of the neutral wire, the occupancy sensor draws a little bit of current via the ground wire for the sensor to function, which is allowed by code because the current is very tiny and completely harmless. The ground wire is required but the neutral wire is not required.

If you don’t have a neutral wire but a ground wire in the switch box, you should choose a “ground required” occupancy sensor switch. These sensor switches have 3 wires, a load wire, a hot wire and a ground wire.

Manual Override

Manual override is a practical feature allowing users to manually override the motion sensor temporarily or permanently to use it as a regular light switch.

Wall Mount Occupancy Sensor

Wall mount occupancy sensors are usually mounted on walls between 8-10 feet above the floor. They might lose sensitivity if they are mounted higher than recommended mounting height. Wall mount occupancy sensors usually have a 110° pattern and a 2500 sq. ft. coverage.

One significant advantage of wall mount occupancy sensors is that they are very flexible with installation. You can locate and install the sensor wherever you need it and further fine-tune the head of the motion sensor to ensure it is precisely pointing at the desired detection area. In contrast, you have fewer installation options when installing sensor switches, as they can only be installed in pre-installed wall boxes.

Ceiling Mount Occupancy Sensor

Ceiling mount occupancy sensors are usually mounted on the ceiling between 8-20 feet above the floor. They might lose sensitivity if they are mounted higher than recommended mounting height. Ceiling mount occupancy sensors can usually have a 360° pattern and a 2000 sq. ft. coverage.

The advantage of ceiling mount occupancy sensors is that they have high detecting performances because they can have a good line of sight when pointed downside on the ceiling and are less likely to be disturbed by normal obstacles on the ground. Ceiling mount occupancy sensors can also be networked with other wall mount or ceiling mount sensors to provide extensive coverage.

High Bay Occupancy Sensor

High bay occupancy sensors are specially designed for high ceilings that normal ceiling mount occupancy sensors cannot cover. High bay occupancy sensors are usually mounted between 20-45 feet above the floor, whereas ceiling mount occupancy sensors can be considered low bay(12-20 feet ). Additionally, high bay occupancy sensors can be both 180° lens end-mount and 360° lens surface-mount unlike ceiling mount occupancy sensors.

Desk Occupancy Sensor

Desk occupancy sensors are mostly used in IoT systems that are installed under the desk to monitor the usage of the desk and human presence in working areas. It has a narrow-angle, 180-degree PIR motion sensor to detect people at the desk without interference from people walking past. Desk occupancy sensors are connected wireless to the IoT systems to communicate the data.

Types of Occupancy Sensors by Power Supply

Low Voltage Occupancy Sensor

Low voltage occupancy sensors are hardwired and powered from a power pack that can convert AC to 24V DC voltage. The lighting and occupancy sensor are connected via the power pack. When the occupancy sensor detects a motion, it will send a control signal to the power pack so as to switch the load or control the lighting.

The advantage of low-voltage occupancy sensors is that you can freely place and install the sensors anywhere on the ceiling without directly disturbing the power lines. Additionally, you can easily wire and connect multiple occupancy sensors in a network via the power pack to provide extended coverage for large spaces like open offices.

Line Voltage Occupancy Sensor

Line voltage occupancy sensors are hardwired and get power directly from 120/277VAC line voltage. It’s also called a self-contained sensor as it does not need a power pack. The lighting is powered and controlled directly by the occupancy sensor. Line voltage sensors are mostly used individually for detecting a small area where a single sensor’s coverage is sufficient for the entire space.

Line voltage occupancy sensors are mostly used when low voltage sensors are difficult to install, i.e., lack of spaces for installing the power pack or junction box is hard to access, as an ideal compact solution.

The disadvantage of line voltage occupancy sensors is that they can only switch about ⅓ or ½ of the load(max load 5A-8A for lighting) compared to a low voltage sensor(max load 16A-20A for lighting) with a power pack.

Wireless Occupancy Sensor

Wireless occupancy sensors are powered by internal batteries without the need for extra wiring. They detect motion and send control singles wirelessly to the controller to switch the load.

Wireless sensors are growing in popularity, especially for upgrading existing lighting controls in your house or office. They are easy and quick to install without the worry of messing with existing wires or adding new wires or power packs.

Occupancy Sensor Features

There are some standard features that occupancy sensors would include.

Time Delay

Time delay is the period of time that delays the light from turning off after the sensor cannot detect any motion in the area. It is an essential feature to keep lighting consistent without turning on and off in circles. When the space is vacant and the sensor cannot detect a motion, the time delay starts to count down. The light is still kept on and the sensor is still looking for moving objects. If it cannot detect any motion single after the time delay expires, the sensor will switch off the load, confirming an empty space.

Occupancy sensors allow users to adjust the time delay settings to suit their demands. Generally, there are several preset time delay options from 15s, 1min, 3min, 5min, and 15min to 30min for users to choose from. The actual time delay will vary by product and application, but it’s generally within the range of several minutes to 1 hour.

The shorter the time delay, the more energy you can save because the lighting will quickly switch off after you leave the room. However, it may cause the lighting to falsely turn off while you are still in the room if the movement is minor and hard to detect, such as reading or working on computers. Longer time delay can solve the problem, but obviously, it will result in more energy waste by keeping the lights on, illuminating an empty room.

That said, choosing the optimal time delay is as important as it can be. Generally, a 15-minute delay for indoor usage is recommended to achieve the most efficient balance of lamp life and energy efficiency. In commercial buildings, The energy code used to require a maximum of 30 minutes time delay but now they have reduced it to 20 minutes for a higher energy-saving efficiency.

Light Sensor / Photocell

Light sensor, photocell, or daylight sensing feature means the occupancy sensor integrates a photocell sensor that is able to detect ambient light along with motion signal. The feature is to prevent the light from turning on in the daytime or when there is sufficient ambient natural light.

Generally, there are several preset light sensor values from 15 lux, 25 lux, to 35lux, or it can be self-adjustable and learn from daily usage patterns. For example, if you select 35LUX and turn on the light sensor, the light will not be activated by any motion when the ambient brightness is above 35lux.

Daylight sensing is a very beneficial feature to help you save energy in the daytime a step further. When there is enough natural light, you don’t have to turn the artificial light on. Natural light is also beneficial for people’s health. If you disable the light sensor, it will behave like a normal motion detector that gets activated whenever a motion is detected.

Sensor Sensitivity

Sensor sensitivity, sometimes known as range, allows users to adjust how sensitive the motion sensor can detect a small at a given distance. All sensor technologies allow users to adjust the sensitivity. The higher sensitivity, the better the sensor can detect a minor motion at a large distance. Thus, sensor sensitivity is also called distance or coverage by different manufacturers.

Generally, setting a high sensitivity is adequate for most scenarios. It’s worth noting that high sensitivity is not always a good thing. If the sensitivity is too high, the sensor may capture activities outside the detecting area which will eventually cause a false-off. For example, the light inside the conference room may turn on when a person simply walks by because the sensor has detected the motion signal via the door or glass. In this case, you can try a low sensitivity to reduce false activations to improve accuracy.

Masking

Masking is a way to partially cover or mask the PIR sensor to limit or adjust its detection range by preventing it from receiving signals from a certain angle or area. For example, if the sensor is frequently getting activated by people from outside the detecting area, you can mask the sensor with tapes to prevent it from detecting signals from that area. This only works with PIR sensors because PIR sensors require to “see” the IR signal.

Some occupancy sensor switches like Leviton may provide a built-in slider for users to limit the detecting range from the two sides. It can be a very convenient feature to further fine-tune the detection accuracy.

Dimming

Dimming is a good complementary feature that expands the flexibility of the occupancy sensor. Besides simply turning the light off in an empty room, dimming occupancy sensors can leave the light at 20% to 50% level to provide minimal visibility without wasting much energy. Dimming occupancy sensors are also called partial-ON, partial-OFF sensors.

Why Use an Occupancy Sensor

There are plenty of good reasons to use an occupancy sensor than a manual light switch. We’ll talk about some good reasons here.

Maybe You Are Interested In

Save Energy and Electric Bills

Using occupancy and vacancy sensors is a key strategy for saving lighting energy. On average, occupancy and vacancy sensors can save 30% to 60% lighting energy in residential and commercial applications, some even up to 80% energy saving.

According to the US Department of Energy, today’s commercial building consumes 19% of the US energy and lighting accounts for 38% of the electricity usage.

According to the US Environmental Protection Agency, By using automatic shutoff, scheduled shutoff such as occupancy sensors, energy savings can range from 40% to 46% in classrooms, 13% to 50% in private offices, 30% to 90% in restrooms, 22% to 65% in conference rooms, 30% to 80% in corridors, and 45% to 80% in storage areas.

47% of people in the US believe the biggest waste of electricity is the lights left on in an empty room, according to Lutron.

According to the Lawrence Berkeley National Laboratory, occupancy-based strategies can produce average lighting energy savings of 24%.

To save energy is to save your electricity bills, obviously.

Staying Up to Energy Code

In plain words, you have to use occupancy or vacancy sensors because energy codes require you to do so in commercial buildings.

Most energy codes would require an occupancy or vacancy sensor system in commercial buildings. Whether it’s general code like ASHRAE, IECC, or local codes like California’s Title 24, it’s necessary to have a legit lighting saving system, especially the occupancy and vacancy sensors.

ASHRAE and IECC both require automatic shutoff for indoor lighting systems in commercial buildings with a size larger than 5,000 square feet.

For a large space with a predictable rate of occupancy, such as the working hour of the whole floor in the building, scheduled automatic shutoff is the way to go.

But for enclosed spaces with an unpredictable rate of occupancy, such as private offices where people would work late at night. Occupancy sensors are the ideal automatic shutoff of lighting for enclosed, localized places where they can provide distributed control. Occupancy sensors are ideally suitable for enclosed spaces with an unpredictable rate of occupancy, such as private offices, restrooms, lunchrooms, break rooms, meeting rooms and so on.

ASHRAE and IECC both require lighting control in enclosed spaces, with some exceptions. We can install occupancy sensors so that both automatic shutoff and space control requirements are met.

As a result, energy codes limit the maximum control zones for space controls.

ASHRAE requires the controlled area at 2,500 square feet if the enclosed space is less than 10,000 square feet and at 10,000 square feet if the enclosed space is greater than 10,000 square feet.

IECC requires the controlled area at no greater than 5,000 square feet and 20,000 square feet for malls, arcades, auditoriums, single-tenant retail spaces and industrial spaces or arenas where captive-key override is used.

Besides saving energy, occupancy sensors can also provide security by indicating the area is being occupied and reducing light pollution at night.

Add Convenience

By automatically turning the light ON and OFF, people don’t have to touch the mechanical switches when entering a dark room, or with a full-arm that is incompetent to turn ON/OFF the light by hand.

Natural Light Benefits Your Health

Access to sunlight is good for our health. Natural sunlight keeps us from hormonal imbalances on a diurnal basis. Occupancy sensors with light sensors allow people to enjoy the sunlight when there is ample ambient natural light without the need to turn the light on.

Occupancy Sensor Improves Security

When in the dark or at night, occupancy sensors can turn on the light automatically to prevent us from tripping, falling from stairs, or other harm due to not having clear sight.

Occupancy sensors can also indicate an area is full and occupied for security reasons, so we know there are people in the area beforehand.

Occupancy Sensor in IoT

The Internet of Things, or IoT, refers to the network of connected physical objects(things) for the purpose of exchanging data with other devices over the internet via embedded sensors, software, and other technologies. Now there are billions of connected IoT devices today thanks to the inexpensive chips, high bandwidth telecommunication, and of course, all types of sensors added to everyday objects. This means everyday devices like toothbrushes, vacuums, cars, lighting, fans, and machines can use sensors to collect data and respond intelligently to users.

One of the main technologies that have made IoT possible is access to low-cost, low-power sensor technology where occupancy sensors play a big role.

Smart home is a great example of how IoT systems can benefit average end consumers. When the devices are networked and connected, it can significantly improve efficiency by automating daily tasks such as lighting, fans, vacuuming, and the safety of your house by monitoring smoke and other threats with detectors and burglars near your home from security cameras.

Smart buildings, such as commercial buildings, are another example of using IoT applications to drive greater operational efficiencies. IoT devices can make your building smart by reducing energy consumption, monitoring and optimizing working space utilization, and lowering all types of maintenance and operating costs.

Benefits of Occupancy Iot Sensors

Businesses and organizations are growing to pay more attention to the efficiency of their offices, buildings, and businesses. The energy consumption, space allocation decisions, hygiene, user experience, employee productivity and how the space is used can now be backed by the data facts provided by occupancy sensors in their IoT system instead of estimates and approximations.

Building owners and managers are also able to manage space in the most efficient way, given the data on how their building spaces are used. With occupancy monitoring IoT sensors, you can make optimized space management of your building.

The main benefits of IoT occupancy sensors include the following:

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

- Optimize your space utilization so that your employees feel more comfortable with increased productivity

- Manage desk and meeting room usage to reduce double bookings and boost productivity

- Improve your energy efficiency by reducing wastage and save money by controlling the lighting and temperature in vacant spaces.

- Facility managers can handle and arrange spare space more efficiently

Space Utilization

Occupancy sensors allow you to make efficient decisions to manage the space utilization of your building. Occupancy sensors provide real-time visibility and a complete picture of the usage status of desks, meeting rooms, and other public areas. This real-time data enables you to get live information on space utilization of your entire building without the need to physically get there and see for yourself to check room availability. Desk sensors and desk booking systems are great examples serving such purposes.

With the real-time data provided by occupancy sensor monitoring, business managers are able to make organization-wide space optimization decisions to implement specific space-saving strategies for the whole building. You can easily verify the underutilized spaces in your spaces where the desks are not used. You can then improve and enhance such spaces based on how people use your building to transform the space with more value. You can also monitor how your employees interact with the space you provide and improve them accordingly for more productivity.

Traditional working environments are transforming to accommodate remote and hybrid workers as more and more people tend to work from home. Businesses can improve the space utilization and layout with the occupancy data to reduce the space no longer required to reduce space cost or transform into other spaces with more value.

Reduce Energy Waste and Operating Costs

With the occupancy monitoring data, we can extract the minimum, average, and high peak usage of workspaces. Based on the statistics, we can have insight and estimate the exact requirement of various spaces. For example, you can save money and reduce energy costs by controlling the lighting and temperature or automatically shut them off in vacant spaces and allocate more resources to such places when high peaks occur.

In post-COVID, it can be very challenging for enterprises and building owners to estimate the exact space they need, given the changing working patterns mixed with in-office and work-from-home practices. Opmitzting office space costs is increasingly becoming vital for business owners. Building owners or managers can be more flexible in leasing spare spaces to other tenants.

Comfortable Work Environment

Occupancy sensor monitoring can drive the fine-tuning of proper HVAC and lighting conditions for proper temperature and lighting to ensure the employees can have the most comfortable working environment that meets their needs.

Re-entry Plan

Occupancy sensors should be a key part of a building re-entry strategy where social distancing is still considered a critical factor. Occupancy sensors can provide no-touch control to automatically turn on lights, open doors and adjust thermostats without employees to manually contact and touch a thing. It can help you comply with social distancing requirements by counting the number of people in the room and help you limit the space and keep the distance between people without utilizing video or compromising privacy.

Occupancy Sensor vs. Motion Sensor

Though we’ve used the terms and talked about occupancy sensors and motion sensors interchangeably in this article, they are actually two different things. And their name describes their nature and purpose very well.

The occupancy sensor detects the presence of people or animals(mostly people) in the monitored area so that they detect whether the space is occupied by people. The motion sensor, as the name suggests, detects moving objects and responds corresponding to the moving signal.

The difference is apparent that occupancy sensors do not require the monitored target to be moving. One example is the bed occupancy sensor widely used in hospitals. It is a pressure pad placed on a bed that monitors occupancy and automatically alarms if unexpected activities happen. Say, if one elderly does not go to bed or leaves their bed without returning, the bed occupancy sensor will detect the occupancy status and send an alarm to the nurses. In this case, you cannot expect the man who is sleeping at night to be “moving”, in order to get detected by the occupancy sensor.

In contrast, the motion sensor is much simpler to understand. Nearly all motion-activated devices, like motion sensor light, security light, and security cameras, uses motion sensor to detect moving people. Compared to occupancy sensors, motion sensors can only detect moving objects.

Motion sensors can also detect the presence of people by detecting whether the object is moving or not. If a person stops moving and stays stationary in the room, motion sensors are not able to detect his presence.

In the context of lighting control applications, occupancy sensors and motion sensors are the same thing. They all use motion sensors to detect the presence of people. If the person stops moving, the occupancy sensors cannot detect people and will shut off the light.

Technology

To help readers have a better understanding of occupancy sensors and motion sensors. We list some of the common sensor technologies involved in both sensors. Readers can easily tell the difference and common areas between the two concepts.

- Pressure Sensors: Detects the pressure and are used for control and monitoring in thousands of everyday applications. It can also be used to indirectly measure other variables such as fluid/gas flow, speed, water level, and altitude. E.g., air pressure sensor, pressure pad.

- Proximity Sensor: A sensor able to detect the presence of nearby objects without any physical contact. For example, a capacitive proximity sensor or photoelectric sensor might be suitable for a plastic target. An inductive proximity sensor always requires a metal target.

- Photoelectric Sensor: A device used to determine the distance, absence, or presence of an object by using a light transmitter, often infrared, and a photoelectric receiver.

- Video Sensor: Compatures and compares the stationary image with the current image.

- Glass Break Sensor: Detects the sound of glass breaking.

- Vibration Sensor: Measures the amount and frequency of vibration in a given system, machine, or piece of equipment. Those measurements can be used to detect imbalances or other issues in the asset and predict future breakdowns.

- Infrared Sensor: Detects the infrared signal emitted from warm bodies. It can be both a passive infrared or active infrared sensor.

- Microwave Sensor: Actively send and detect the microwave signals reflected from moving objects.

- Ultrasonic Sensor: Actively send and detect the ultrasonic sound signals reflected from moving objects.

These technologies are common explanations with the principle of helping readers build a whole picture of sensor technologies to have an in-depth understanding of occupancy sensors. The main scope of this article focuses on occupancy sensors in the lighting control industry.

Gee – since I invented the darn thing…you might have asked me to contribute a bit…