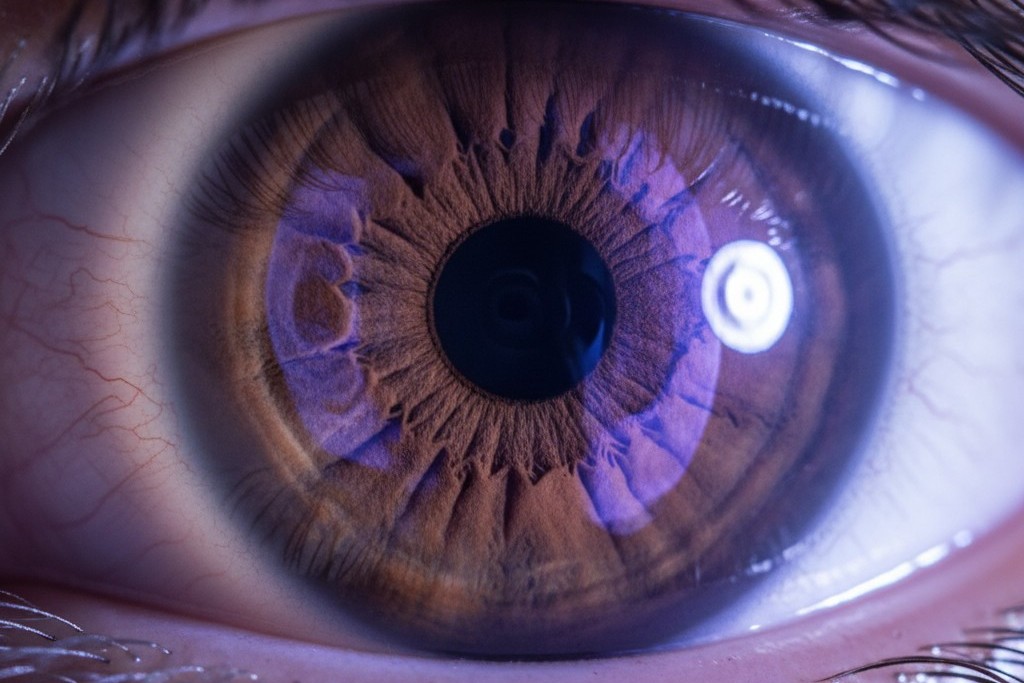

The real threat of ultraviolet sterilization isn’t the radiation itself. We know exactly what 254nm light does to organic tissue: it shreds DNA and halts cellular replication. The problem is that it does this to your corneas just as efficiently as it does to mold spores on a petri dish, and it does it silently.

There is no heat warning. There is no immediate pain. A hobbyist might reach into a curing chamber to adjust a sample, relying on a manual toggle switch they swore they turned off. Two minutes of exposure later, they finish the job and go to bed. Four hours later, they wake up screaming because their eyelids feel packed with hot sand. This is photokeratitis. The damage is already done, and the only remedy is time, darkness, and perhaps a bottle of tetracaine drops if the ER is feeling generous.

Memory is not a safety feature. Humans are the weak link in any containment system. If you are building a UV-C curing station, a laminar flow hood, or a sterilization room, you need a system that assumes you are going to be careless. You need a kill-switch that works faster than you can think.

The Latency Trap of “Smart” Sensors

The instinct for the modern DIYer is to grab a spare smart home sensor and tie it to a smart plug. You take a Zigbee motion sensor, pair it with a hub, and write a simple automation: “If motion detected, turn off smart plug.”

Do not do this.

This logic chain is unfit for life safety. Consider the signal path: The sensor detects motion, wakes up from a low-power sleep state, and negotiates a handshake with your hub. The hub processes the logic—or worse, sends an API call to a cloud server in AWS East. The command is routed back down to the smart plug, which finally cuts the power.

I have clocked this sequence on consumer hardware. Even on a local network, latency can drift between 800 milliseconds and 1.5 seconds. If the cloud is involved, or if your Wi-Fi router is negotiating a channel hop, that delay can spike to five seconds. In the context of UV-C intensity, a one-second delay is an eternity of exposure. You are effectively betting your vision on the uptime of a server farm in Virginia.

Worse, consumer smart gear fails in the “dangerous” state. If the Wi-Fi drops, the automation fails and the lamp stays on. If the sensor battery dies, the lamp stays on. If the hub freezes during a firmware update, the lamp stays on. You need a system where the failure of any component results in the lamp turning off immediately.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

Gravity, Copper, and Normally Closed Logic

The industrial standard for this problem is “Normally Closed” (NC) logic. It is the only acceptable architecture for a safety interlock.

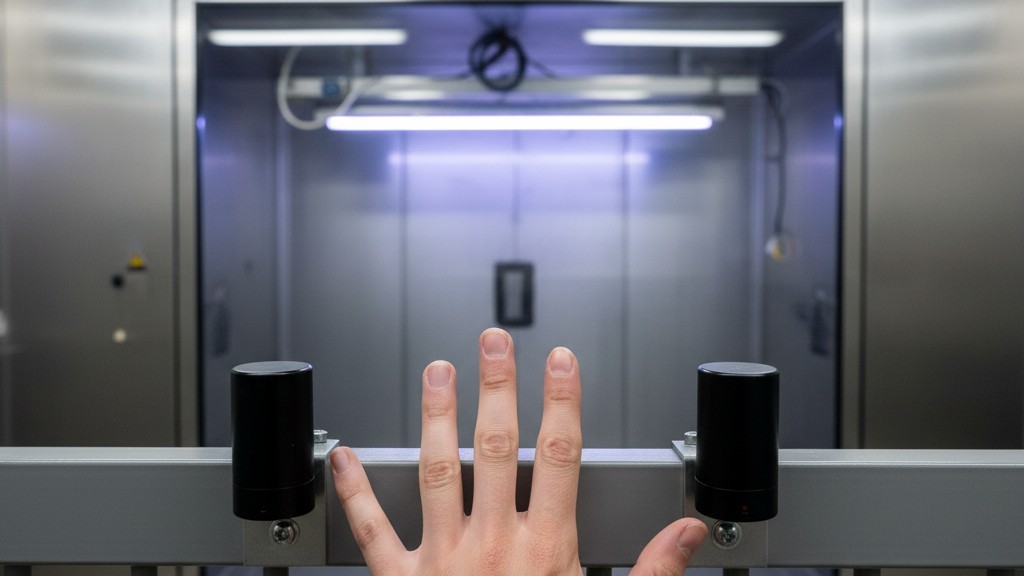

In a Normally Closed system, the safety circuit is a continuous loop of electricity that must be actively maintained to keep the machine running. The sensor or switch is closed (conducting electricity) only when it is safe. The moment that loop is broken—by a door opening, a beam breaking, or a wire being cut—gravity or a spring forces the power relay open, killing the light.

Maybe You Are Interested In

Think of an elevator brake. It isn’t held open by a lock; it’s held open by power. If the power fails, the brake clamps down instantly. Your UV setup must work the same way. You aren’t sending a signal to “turn off” the light. You are physically interrupting the power that allows the light to exist.

This is why simple perimeter beams—like the safety sensors at the bottom of a garage door—are often superior to complex digital sensors. A set of Chamberlain or Genie safety beams creates an invisible tripwire. The receiving eye expects a constant signal from the sending eye. If you walk through it, you physically block the photons. The circuit opens. The relay drops. There is no software to interpret the event. The physics of the circuit dictates that the power must cut.

Seeing What Humans Can’t

If you must use volumetric sensing (detecting motion inside a room rather than just a perimeter tripwire), you run into the problem of “blind time.” Standard Passive Infrared (PIR) sensors—the kind used for porch lights—are designed to detect large, lateral movements across their field of view. They are terrible at detecting micro-movements.

If you walk into a room and stand still to inspect a print, a cheap PIR sensor will decide the room is empty and allow the UV lamp to strike. This is the difference between “Occupancy” (turning lights on for convenience) and “Safety” (keeping lights off for survival). You aren’t trying to save electricity here; you are trying to prevent burns.

For a true safety curtain, you want “Dual Technology” sensors. These units, like the Bosch Blue Line Gen2 series, combine PIR with Microwave Doppler radar. The microwave element actively floods the space with energy and looks for the frequency shift caused by moving objects. It is far more sensitive to small movements, like breathing or shifting weight.

Microwave sensors have a dangerous quirk, though: they can see through drywall, glass, and plastic. If you build a curing box out of acrylic, a microwave sensor inside might detect you walking past the box and kill the cycle unnecessarily. Conversely, PIR cannot see through glass. You must match the sensor physics to your containment material. If you are using a glass enclosure, PIR is safe. If you are guarding an open room, Dual Tech wired in series is the standard.

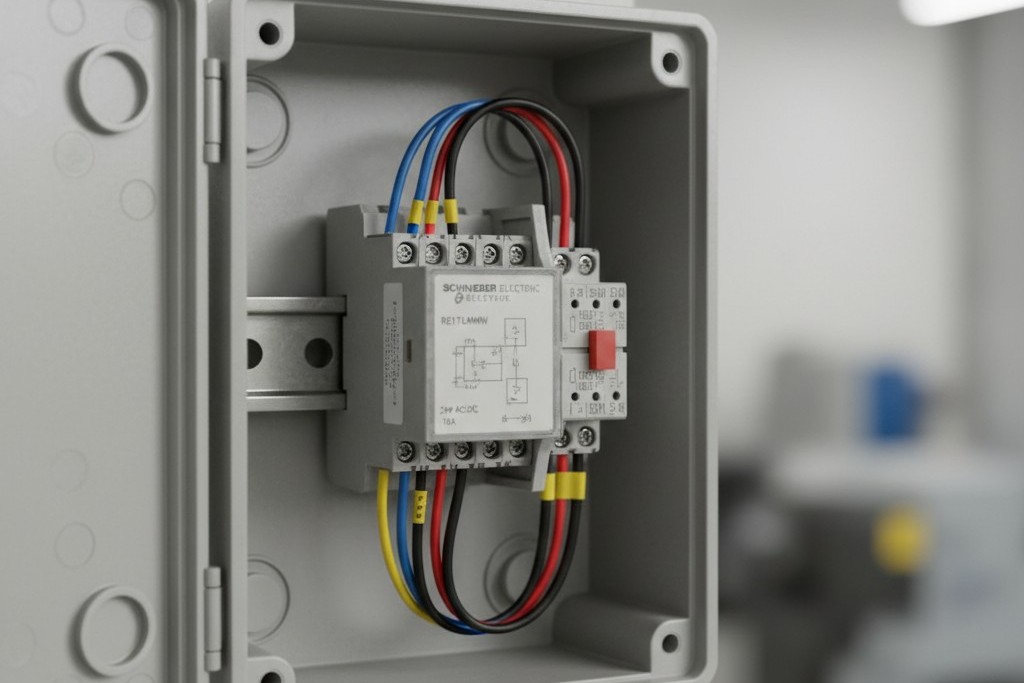

The Click of Safety: Isolating Voltage

You can’t wire these low-voltage sensors directly to your 120V or 240V UV ballast. You will let the magic smoke out of the sensor, and likely yourself. You need a physical interface that separates the logic voltage (usually 12V or 24VAC) from the load voltage.

This is where the “RIB” (Relay in a Box) or a dedicated contactor comes in. A device like the RIBU1C allows you to run a safe, low-voltage control loop through your sensors and door switches. When that loop is closed, the RIB’s electromagnet pulls the high-voltage contacts together with a distinct, mechanical clack.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

That sound is important. It is the sound of a physical air gap closing. When the safety loop is broken, a spring forces those contacts apart. It doesn’t matter if the microcontroller crashes or the Wi-Fi is down. The spring does not care. It obeys the laws of physics, snapping the circuit open and severing the power to the ballast.

The Walk Test Ritual

Once you build this, don’t trust it. Test it.

Every time you set up a new run, perform a functional check. Start the cycle, then trigger the safety—open the door, wave a hand past the beam, cut the power to the sensor. You should hear the relay click off instantly. There should be no hesitation.

If you are working with Far-UVC (222nm), you will read marketing claims that it is safe for human skin and eyes. Treat those claims with extreme skepticism. Regulations lag behind technology, and manufacturing tolerances vary. Treat every UV source as if it is a loaded weapon. Trust the interlock, not the wavelength.

The goal is a system that protects you from your own complacency. When you are tired, rushing, or distracted, the machine must be smarter than you. It must fail into safety, every single time.