The phone rings at 2:14 AM. Never a polite time. The monitoring station reports an alarm at Zone 4—the North Loading Dock. The facility manager drags themselves out of bed, drives twenty minutes on icy roads, and meets the police at the site. They walk the perimeter. The doors are locked. The glass is intact. The warehouse is silent, empty, and cold. But the keypad insists: Alarm Memory: Zone 4. The police officer hands over a citation for a false dispatch—usually starting at $250—and leaves. This happens again on Tuesday. By Thursday, the facility manager is ready to rip the sensor off the wall with a claw hammer.

The sensor isn’t broken. It’s doing exactly what it was designed to do. The issue is that nobody checked the physics of the environment before screwing it into the drywall. A loading dock is not a hallway. It is a chaotic intersection of thermal violence, air pressure differentials, and loose debris. Treat it like an office corridor, and you will pay for it in sleep and municipal fines.

The Physics of the “Ghost”

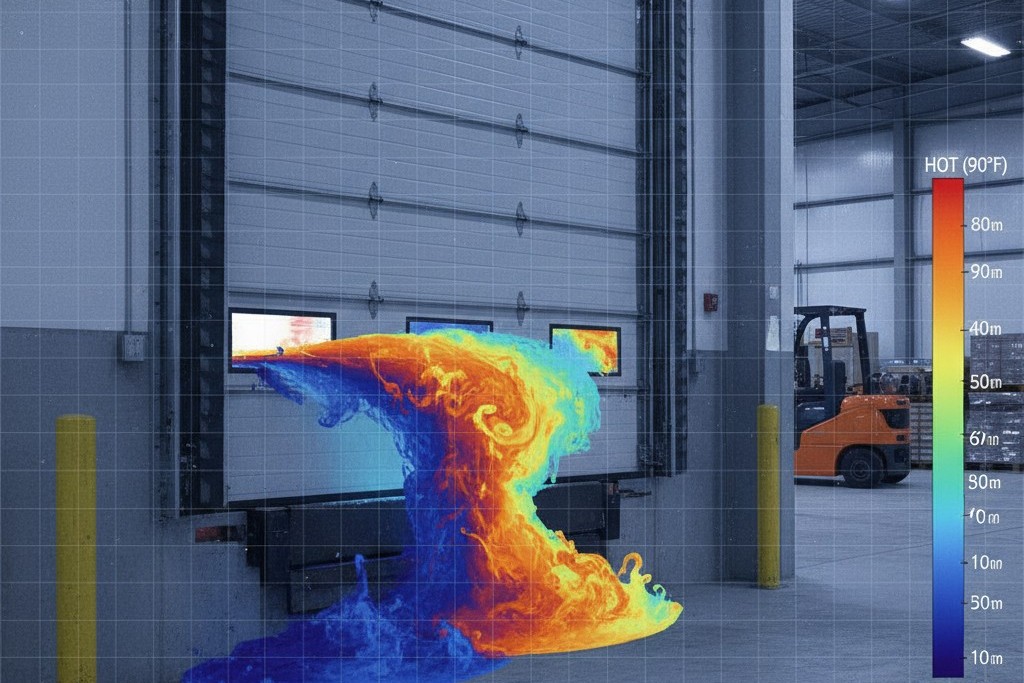

To stop the false alarms, you have to understand what the sensor is actually seeing. Most standard motion detectors are Passive Infrared (PIR). They do not “see” motion in the way a camera does; they see heat signatures moving across a grid. The sensor looks out at the world through a faceted lens that divides the room into positive and negative zones. When a human body—emitting roughly 98°F of heat—walks across those zones, the sensor registers a rapid change in infrared energy. The chip says “Intruder” and trips the relay.

In a climate-controlled office, this works perfectly. But a loading dock is a thermal nightmare. When a dock door has a gap in the seal—and they all do eventually—sub-zero wind from a Midwest winter night forces its way into the heated warehouse. This isn’t just air; it acts as a thermal solid to a PIR sensor. A blast of -10°F air hitting a pocket of +60°F interior air creates turbulent eddies that swirl and move. To a standard PIR sensor, that moving cloud of cold air looks remarkably like a person walking briskly across the floor. The sensor sees the temperature differential moving across its zones, assumes it’s a thief, and wakes you up.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

You have to distinguish between security and convenience here. If you are reading this because the high-bay LED lights keep turning on when nobody is there, the physics are the same, but the stakes are lower. A light turning on costs you pennies in electricity. A burglar alarm screaming at 3 AM costs you police credibility and real cash. You can tolerate a “chatty” lighting sensor; you cannot tolerate a chatty intrusion sensor.

The Poltergeist is Usually Shrink Wrap

If the temperature shift doesn’t trigger the alarm, the trash will. This is where the second common technology—Microwave—often betrays you. Many installers, burned by the PIR thermal issues mentioned above, switch to Microwave sensors. These work like a police radar gun: they flood the room with microwave energy and wait for it to bounce back. If objects are stationary, the frequency returns unchanged. If an object moves, the frequency shifts (the Doppler effect), and the alarm trips. Microwave sensors are great because they don’t care about temperature. They can see through cold drafts.

But they also see through cardboard boxes, drywall, and sometimes the dock door itself. More importantly, they are incredibly sensitive to the “Trash Tornado.” I once troubleshot a facility in Kansas City where the alarm tripped every time a storm front moved through. The sensors were high-end, expensive units. The installation was clean. But down on the floor, near the bay door, lay a pile of discarded plastic strapping and shrink wrap.

When the wind hit the dock seals, it created a vortex inside the bay. That pile of plastic trash would lift up, swirl in a circle for three seconds, and settle back down. To the microwave sensor, that swirling plastic had the exact same Doppler signature as a crouching man moving 3 feet per second. The sensor wasn’t malfunctioning; it was accurately detecting a moving object. The facility manager didn’t need a new security system. They needed a broom. Housekeeping is a layer of your security calibration. If you leave low-mass debris in a high-draft zone, you are building a false alarm generator.

Dual-Technology: The Only Valid Defense

You cannot rely on PIR alone at a dock (thermal drafts will trip it). You cannot rely on Microwave alone (moving trash or rattling doors will trip it). The only professional solution for a loading dock environment is Dual-Technology with AND Logic.

These sensors contain both a PIR element and a Microwave transceiver inside the same housing. The critical feature is the “AND” gate logic. For the alarm to trip, the PIR must see a heat differential AND the microwave must see physical motion at the exact same time.

Maybe You Are Interested In

Think about the wind draft scenario: The cold air blasts in. The PIR sees the temperature change and screams “Intruder!” But the Microwave sensor looks out and sees no physical object moving—just air. It votes “No.” The system stays silent.

Now think about the trash scenario: The wind swirls the plastic wrap. The Microwave sees the movement and screams “Intruder!” But the PIR looks at the plastic and sees that it is the same temperature as the floor. It creates no thermal contrast. The PIR votes “No.” The system stays silent.

Only a real human—who has both body heat and physical mass—will trip both sensors simultaneously. If you are managing a warehouse, go look at the sensors protecting your overhead doors. If they are generic “white box” units from a big-box store, they are likely simple PIR. Replace them with industrial-grade Dual-Tech units from reputable manufacturers like Bosch (Blue Line or ISC series) or Optex (CX/DX series). Look for the “AND” logic specification. Do not let an installer sell you a “Quad PIR” and tell you it’s the same thing. It isn’t.

Geometry and The Art of Masking

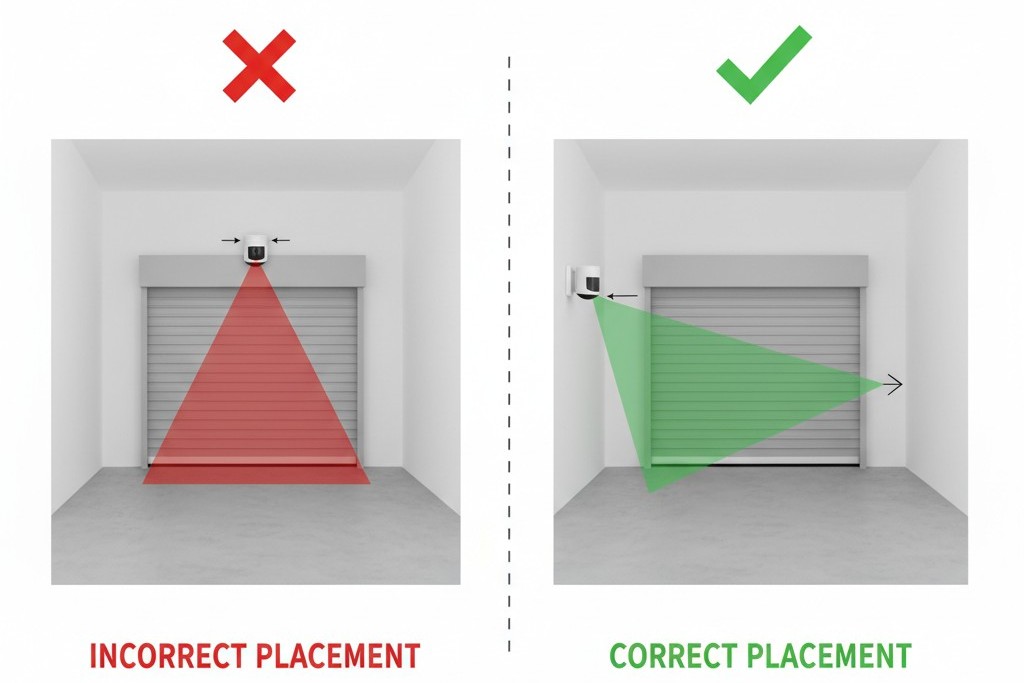

Even the best sensor will fail if you point it at the sun. Amateurs often mount the sensor on the back wall, facing directly at the loading dock door. This creates two problems. First, when the door opens during the day, the sensor is blinded by direct sunlight, which floods the infrared receiver and can cause false triggers or permanent damage. Second, it places the most volatile area (the door gaps) in the most sensitive part of the sensor’s view.

The correct geometry is almost always a “curtain” or “cross-trap” setup. Mount the sensors on the side walls, looking across the door rather than at it. This way, the sensor catches an intruder entering the space, but its field of view doesn’t stare directly into the shaking, leaking door seal.

While you are up on the ladder, check the masking. Most industrial sensors come with small plastic strips or mirrors that allow you to block off parts of the lens. If you have a heater vent, a hanging sign that sways, or a loose door track that rattles, mask that specific slice of the view. You don’t need to detect motion three inches from the ceiling; you need to detect a person on the floor.

Check your door contacts, too. If your alarm panel says “Door Forced” rather than “Interior Motion,” you aren’t dealing with a sensor issue at all. You’re dealing with a magnet gap issue. Wind rattles the big metal track, the magnet moves too far from the reed switch, and the alarm trips. Tighten the track or switch to wide-gap armored contacts. Don’t blame the motion detector for a loose door.

Why Not Just Use Cameras?

IT directors love to solve this with software. “Why don’t we just use AI video analytics?” they ask. “The camera can tell it’s a person.”

In a perfect world, yes. In a warehouse, no. Loading docks are dirty. Diesel soot, dust, and spider webs accumulate on camera lenses rapidly. Video analytics software relies on a clear, sharp image to classify objects. When that lens gets a layer of grime, or when the sun glares off the polished concrete floor, the “AI” starts hallucinating. It sees a shadow and thinks it’s a truck. It sees a moth on the lens and thinks it’s a person.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

Furthermore, cameras require bandwidth, licenses, and constant firmware updates. A high-quality Dual-Tech motion sensor uses simple copper wire, runs on 12 volts, creates zero network traffic, and works for fifteen years without a software patch. For critical intrusion detection, simple physics usually beats complex software.

Housekeeping is Security

The most cost-effective fix for false alarms won’t be found in the Grainger catalog. It is a roll of weather stripping and a shop vac. If you seal the gaps in the dock levelers, you stop the thermal turbulence that tricks the PIR. If you sweep the loading bay floor before locking up, you remove the debris that tricks the Microwave.

The sensor is a dumb instrument. It does not know the difference between a burglar and a tumbling piece of cardboard. It relies on you to create an environment where the only thing that moves is something that shouldn’t be there.