You don’t realize how dangerous your grow room is until the lights go out. I’ve seen it happen a dozen times: a grower is working late in the lung room (the staging area outside the tent where the real work happens), balancing a five-gallon Homer bucket of nutrient solution in one hand and a pH pen in the other.

The overhead lights are off to preserve the dark cycle in the adjacent flower room. They’re navigating by the weak beam of a headlamp, or worse, a flashlight clenched between their teeth. Then the inevitable happens. They trip over a ballast cord or a feed line. The bucket goes down, five gallons of water hits the epoxy floor, and suddenly they are scrambling in the pitch black trying not to mix water with the 120-volt outlets near the floor. It’s a disaster that costs money, hurts pride, and occasionally fries equipment.

The solution isn’t a brighter flashlight. The solution is treating your workspace like an industrial facility, not a closet. In a commercial build, we don’t rely on the operator to flip switches when their hands are covered in resin or phosphoric acid. We let the room see the operator. This is where a simple piece of hardware like the Rayzeek RZ022 plug-in motion sensor becomes critical infrastructure. The plant doesn’t care about motion sensors. This gear is for you—keeping the workflow safe without involving a single app, server, or Wi-Fi password.

The Hardware Reality: Physics vs. Code

My rule for equipment in high-humidity, high-stakes environments is simple: if it needs an internet connection to turn on, it doesn’t belong in the garden. I’ve watched clients lose entire crops to powdery mildew because a “smart” humidifier plug decided to do a firmware update at 3 AM and defaulted to “OFF” when the server couldn’t reconnect. We don’t play those games with electrical infrastructure.

This is why I prefer the Rayzeek units over the endless sea of Tuya-based smart plugs on Amazon. The Rayzeek RZ021 and RZ022 utilize PIR (Passive Infrared) technology. They aren’t “watching” you with a camera; they look for a differential in heat signatures. A Fresnel lens on the front creates a series of detection zones. When a warm body moves across those zones, the sensor physically closes a relay and power flows. It is a mechanical response to a physical reality.

Growers need to watch out for a specific nuance here. Some newer sensors use radar or microwave detection, which sounds high-tech until you realize radar can penetrate thin barriers. I’ve seen radar sensors detect motion inside a grow tent and turn on the lights outside, or vice versa. PIR requires a line of sight. It won’t see through your Mylar tent walls. This means you can have a Rayzeek controlling the lung room task lights without it accidentally triggering every time a fan oscillates inside the tent. It stays local, it stays dumb, and it works every time you walk in.

Separation of Powers: Task Lights vs. Grow Lights

Here is the hard line that beginners often blur: You are never, under any circumstances, plugging your main grow light driver into a motion sensor.

Your plants operate on a strict circadian rhythm—usually 18/6 for veg or 12/12 for flower. If you put a 600-watt LED bar on a motion sensor, you create a chaotic strobe effect that will stress the plant into hermaphroditism faster than a light leak. I’ve seen a crop of Gorilla Glue #4 seed out completely because a grower thought it would be cool to have the “sun” come on when he walked in.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

The motion sensor is for task lighting. These are the shop lights, the T5 fluorescents, or the simple green LED bulbs you use to see what you are doing. By isolating the task lighting on a sensor, you solve the “dark cycle anxiety” that plagues so many home growers. You know the feeling: you need to mix a reservoir change at 9 PM, but the tent is in its dark period. You’re terrified of turning on the main room lights and leaking photons into the intake vents.

I also see a lot of confusion on forums regarding “green light” safety. People ask if they can just work under green light all night. While cannabis is less sensitive to the green spectrum, high-intensity green light can still interrupt the photoperiod if it’s bright enough. The safer bet is to have your green work light on a Rayzeek sensor. It turns on when you enter to do the work, and more importantly, it turns off the second you leave. It removes the human error of forgetting to flip the switch, ensuring your dark cycle remains sacred even if you’re forgetful.

The Wet-Hand Workflow Test

I evaluate gear using a specific mental model called the “Wet-Hand Test.” Imagine you just finished pruning a mother plant and your hands are sticky with resin. Or you are midway through pH-balancing a reservoir, hands wet with nutrient solution. Do you really want to reach out and toggle a wall switch? Do you want to pull your phone out of your pocket, unlock it with your face, find an app, and tap a button? Absolutely not.

In a properly set up lung room, you walk in, and the lights snap on. You mix your nutrients, check your run-off, and carry the waste bucket out. You never touch a switch. This is hygiene, not just laziness. Every time you touch a switch, you transfer spores, bacteria, or pests from the garden to the house, or vice versa. By using a plug-in sensor at the outlet level—usually positioned near the entryway or above the workbench—you eliminate a primary contact point.

I recently helped a client struggling with contamination in his garage grow. We traced part of the problem to the door handle and the light switch, which were covered in grime. We swapped his overhead shop lights to a Rayzeek RZ022 plugged directly into the ceiling outlet. Now, he walks in, the lights trigger, and he touches nothing but the plants and the tools. It’s a cleaner, faster way to work.

Maybe You Are Interested In

Tuning the Sensor: Avoiding the Disco Effect

The one complaint I hear about motion sensors is the “disco effect”—the lights turning off because you stood still for ten seconds to read a label on a bottle of General Hydroponics FloraGro. This is why you don’t buy the cheapest sensor on the shelf. You need one with an adjustable time delay.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

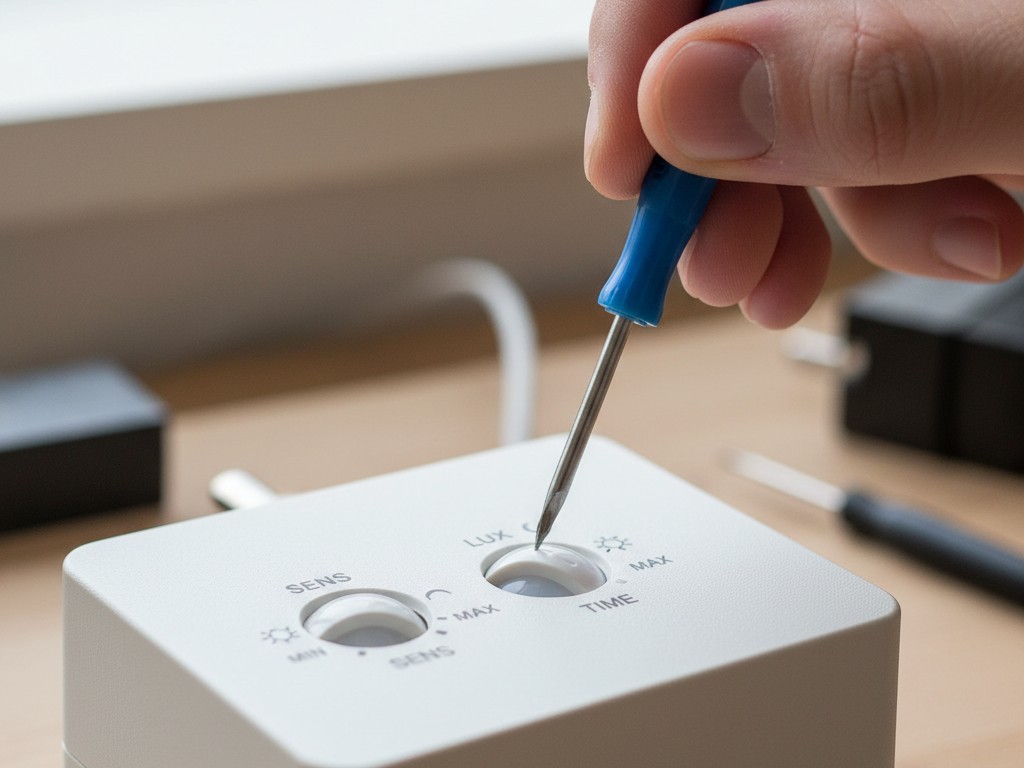

On the Rayzeek models, there is usually a small dial or a set of dip switches on the back or under a cap. I recommend setting this to at least 5 minutes for a grow room environment. You aren’t just walking through; you are working. You might be standing still calibrating a BlueLab pen for three minutes. You don’t want to be waving your arms around like a wacky inflatable tube man just to keep the lights on.

Also, be aware of the “inductive load” if you use older fluorescent fixtures with magnetic ballasts. When these turn on, they pull a massive spike of power—inrush current—that can weld the delicate relays in smaller smart plugs. The Rayzeek units are generally robust and rated for decent amperage, but I always tell people to check the label. If you’re running a massive bank of shop lights, check the total amperage. If it’s close to the limit, use the sensor to trigger a heavy-duty contactor instead. But for 99% of home growers using LED shop lights, the plug-in unit is plenty.

The Bottom Line

You don’t need to be an electrician to make your grow room safer, and you certainly don’t need more apps on your phone. You just need to respect the environment you are working in. It’s wet, it’s often dark, and your attention is usually focused on the plants, not on where you are stepping. Automation in this context is a safety rail, not a luxury. Put your task lights on a sensor, keep your hands free for the heavy lifting, and let the physics do the work.