The lights cut out mid-fold. You’re standing over a basket of warm laundry, hands still smoothing a towel, when the room plunges into darkness. You wave an arm, the lights flicker back on, and three minutes later, the cycle repeats. This isn’t a defective sensor; it’s a geometry problem.

Occupancy sensors in small laundry rooms have a predictable failure mode that has little to do with quality and everything to do with physics and layout. The issue is compounded in tight spaces, especially rooms under 80 square feet with pronounced rectangular shapes. Here, the sensor’s detection cone simply cannot cover the corners while also monitoring the central work zone. The problem intensifies during stationary tasks like folding, where you remain present but fall outside the narrow band of motion the sensor can reliably detect.

This is where wall-box occupancy sensors, when positioned correctly, solve a geometric puzzle that ceiling-mounted units cannot. And it’s where the distinction between quality models like Rayzeek and generic imports becomes critical, as default settings, durability, and detection consistency determine whether a sensor is a solution or a source of chronic frustration.

The Folding Blind Spot in Tight Laundry Rooms

False-offs during laundry folding follow a familiar pattern. You enter the room, triggering the sensor. The initial motion of walking to the counter or transferring clothes from the dryer registers clearly. But once you start folding, your movement becomes small and repetitive. Your arms move in a narrow plane while your torso remains stationary. If you’ve shifted into a corner for more counter space, you may have also moved out of the sensor’s primary line of sight.

So why does this happen? Passive infrared (PIR) sensors work by detecting changes in heat across their field of view. A person walking through a room creates a large, rapid thermal change as their body moves from one detection zone to another. A person standing still and folding a towel creates a minimal thermal change. The heat signature is constant, and small hand movements may not cross enough detection zones to register as occupancy. This stationary motion threshold is a fundamental characteristic of PIR technology, not a flaw.

The problem is more severe in small rooms because spatial constraints force compromises in sensor placement. A six-by-eight-foot laundry room offers few good mounting positions, and its rectangular aspect ratio creates inherent coverage challenges. The sensor has to monitor the entryway, the washer and dryer, and the folding counter, which might span the room’s entire length. In larger spaces, overlapping detection zones or the natural movement of occupants compensates for stationary periods. In a tight laundry room, there is no margin for error.

The task itself makes things worse, as folding often happens in the least favorable spot: against a wall or in a corner. Laundry rooms are utilitarian spaces where the counter is often just a narrow ledge. This forces you into a position where you are stationary, perpendicular to the sensor’s optimal detection axis, and potentially outside its horizontal spread.

Maybe You Are Interested In

How Detection Geometry Creates Coverage Gaps

To understand why wall-box sensors outperform ceiling mounts in these spaces, we have to look at the geometry of their detection cones and how they interact with room dimensions.

PIR Sensor Detection Cones and Horizontal Limits

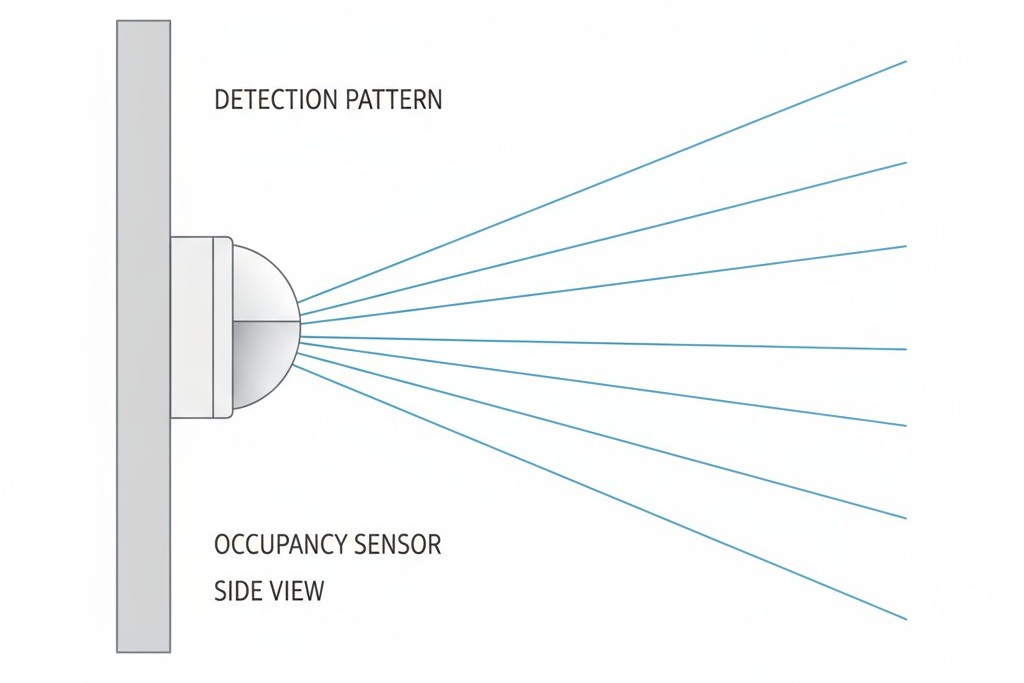

A PIR sensor’s detection zone isn’t a uniform sphere; it’s a cone, or a series of overlapping cones, shaped by its lens. This cone is defined by its vertical and horizontal fields of view. A typical wall-box sensor might have a horizontal spread of 110 to 150 degrees, creating a detection volume that fans out from the wall.

This horizontal spread determines how much of a room’s width the sensor can see. While a 120-degree field of view covers a substantial area directly in front of the sensor, this coverage degrades sharply at the edges. The detection range—the maximum distance for reliable motion detection—is strongest along the central axis and weakens toward the periphery.

In a rectangular room, this creates a predictable blind spot. If a sensor is mounted on a short wall, aiming down the room’s length, the far corners are both distant and off-axis. Even with a generous 150-degree spread, the sensor’s cone may not reliably cover these zones. The farther away you are from the sensor, the more your movement has to stretch to the sides, and the less sensitive the detection becomes. Movement in a far corner must be far more pronounced to register than movement directly in front of the sensor.

The Corner Penalty in Rooms Under 80 Square Feet

Small rooms amplify this corner problem. In an eight-by-ten-foot laundry room, the diagonal distance from one corner to its opposite is nearly 13 feet. If a single sensor is mounted near one corner, the opposite corner is at the extreme edge of its range and far off-axis.

Laundry rooms also have cluttered sightlines. Shelving, stacked appliances, and hanging clothes can all obstruct the sensor’s view. A shelf protruding from a wall can create a shadow zone where motion is invisible. In a larger room, you’d likely move in and out of these shadows. In a tight laundry room, you might remain in a shadow zone for an entire task.

The room’s aspect ratio matters as much as its area. A square eight-by-eight-foot room is easier to cover than a rectangular four-by-sixteen-foot room of the same area. The rectangle forces a sensor to choose between covering a long, narrow corridor with weak corner access or covering the width with limited depth.

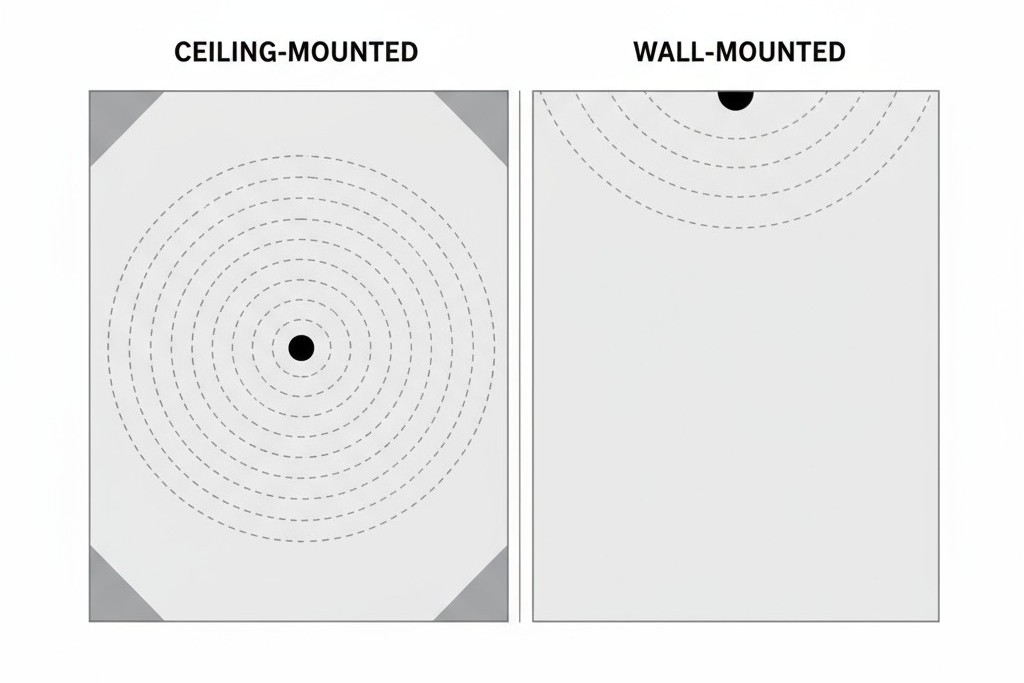

Ceiling-mounted sensors introduce their own geometric handicap. Their detection cone aims downward, creating a pattern on the floor that is strongest directly below and weakest toward the walls. The corners are at the extreme edge of this downward cone. A person standing in a corner, close to the wall, may be partially hidden from the sensor’s view or simply too far off the central axis to trigger detection, especially with minimal motion.

The Wall-Box Advantage: Better Angles, Better Coverage

Wall-box sensors, mounted at a typical switch height of four to four-and-a-half feet, orient their detection cones horizontally across the room. This alignment perfectly matches the plane of human activity, where tasks happen at counter height or involve standing and walking.

The advantage is simple geometry. A wall-box sensor projects its detection cone parallel to the floor, directly intersecting activity zones like the folding counter and the path to the dryer. In a six-by-eight-foot room, a sensor on a six-foot wall can cover the full eight-foot depth with its primary range while capturing the entire width in its horizontal spread.

Corners become accessible because the horizontal cone sweeps along the wall, rather than dropping from above. A person folding laundry at a corner counter is positioned squarely within the sensor’s field of view. A ceiling-mounted sensor, by contrast, sees that same person as a small target at an oblique downward angle, where its sensitivity is weakest.

In laundry rooms with low ceilings, common in basements, the ceiling-mount disadvantage worsens. A lower ceiling shrinks the horizontal spread of the downward cone, concentrating the detection pattern and making it less effective at the room’s perimeter. Wall-box sensors are unaffected by ceiling height, as their horizontal projection is independent of the distance to the floor.

The horizontal orientation also aligns better with how people enter a room. Walking forward into a laundry room means you cross multiple detection zones of a wall-mounted sensor rapidly, creating a strong, unambiguous trigger.

Rayzeek vs. Generic: Why Build Quality Matters

In the specific context of a laundry room, the functional differences between Rayzeek wall-box sensors and generic alternatives are significant. Three factors directly affect long-term performance: default settings, control durability, and component quality.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

The Superiority of Vacancy Mode

Occupancy mode (auto-on, auto-off) and vacancy mode (manual-on, auto-off) serve different purposes. For laundry rooms, vacancy mode is the clear winner. Laundry tasks are intermittent; you might pop in for 30 seconds to transfer clothes and leave. Occupancy mode would trigger the lights for every brief entry, wasting energy while the washer or dryer runs. Vacancy mode ensures the lights activate only when you decide you need them for manual tasks like sorting or folding.

It also changes the user’s expectation. With full automation, any failure is frustrating. With vacancy mode, you’ve already engaged with the system manually; you just expect it to turn off correctly, a much simpler and more reliable task.

Rayzeek models default to vacancy mode. Generic imports often default to occupancy mode, requiring a configuration change that many users never make. The result is a sensor set up for the wrong job, leading to wasted energy and dissatisfaction.

Tactile Controls for Humid, Dusty Environments

Laundry rooms are humid and dusty. This isn’t about user preference; it’s about environmental durability. Tactile switches—physical buttons that click—use a simple, enclosed mechanical contact to complete a circuit. Lint, detergent dust, or moisture on the surface won’t stop them from working.

In contrast, membrane switches and capacitive touch controls rely on detecting pressure or proximity. Moisture can interfere with capacitive sensors, while dust can work its way under a membrane button, preventing it from making contact. In this environment, their failure is not a matter of if, but when.

Rayzeek sensors use durable, tactile mechanical switches. Generic imports often opt for cheaper membrane or touch controls for a sleeker look. That cost saving comes at the price of durability, a penalty that becomes obvious within months of installation in a busy laundry room.

Internal Components and Long-Term Reliability

A sensor’s true quality lies in its internal components: the PIR module, the relay switch, and the power supply. Rayzeek models use multi-element PIR sensors and precisely designed Fresnel lenses for wide, even coverage. The relay that switches the lights is a robust electromechanical component rated for tens of thousands of cycles.

The audible click of the relay is itself a signal of quality. It indicates a physical relay is at work, not a cheaper triac or solid-state switch that can generate more heat and fail sooner under the electrical noise common on a laundry circuit.

Generic imports often use lower-cost modules with fewer PIR elements, resulting in less sensitive detection at the edges of their stated range. Their switching mechanisms may be underspecified, leading to premature failure. Their power supplies may lack the circuitry to protect against voltage spikes from the washer and dryer motors. Individually, these are small compromises. Together, they create a sensor with a measurably shorter and less reliable service life.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

Choosing the Right Sensor for Your Room

The decision to use a wall-box sensor, specifically a quality model, comes down to your room’s geometry and how you use it.

Wall-box sensors are essential in rooms under 70 square feet with rectangular shapes (aspect ratios wider than 1.3 to 1). In a six-by-ten-foot room, a ceiling mount will struggle to see the far corners where folding happens. A wall-box sensor, aimed down the room’s length, provides direct, reliable coverage of that zone. They are also superior in rooms with obstructions like shelving or stacked appliances, as their horizontal line of sight is less likely to be blocked.

For larger, more square rooms, ceiling mounts can be viable, but the core principles of build quality still apply. The vacancy mode default, durable tactile controls, and high-quality internal components will ensure reliable performance regardless of the room’s shape.

While the energy savings from a laundry room sensor are modest, they eliminate nearly all the waste from a light left on by mistake. The return on investment is measured in months. Ultimately, the choice comes down to application fit and long-term durability. A well-designed wall-box sensor aligns with the unique demands of a laundry room: horizontal detection for tight spaces, vacancy mode for intermittent use, and durable controls for a challenging environment. The result is simple: the lights stay on when you need them and turn off when you don’t.