Portable electric heaters are a winter mainstay in workshops, studios, and home offices—any space where central heating falls short. They are also a leading cause of fires. The heater itself isn’t the problem; the danger lies in how we use it. A heater left running in an empty room combines high heat with a total lack of supervision, creating a window of vulnerability that grows with every unattended minute.

Beyond the fire risk is the simple fact of energy waste. A 1,500-watt space heater running for eight hours consumes 12 kilowatt-hours of electricity. Day after day, this adds up to a substantial winter utility bill. Many users tolerate this waste because the alternative—manually flipping the heater on and off with every entry and exit—is simply impractical.

Occupancy-based automation addresses both safety and cost with a single, intelligent mechanism: a cutoff that kills power to the heater when the room is empty. By using motion-sensing smart outlets or occupancy sensors, we introduce conditional logic to a simple on-off device. The heater gets power only when human presence is detected and loses it when the room empties. This transforms a passive appliance into a supervised system, one that operates within clear boundaries of safety and efficiency.

But this approach is only effective if implemented correctly. Not all heaters are suitable for this kind of control, and not all sensors work for every space. Power ratings, sensor technology, heater response times, and the nature of the work being done all impose constraints. Getting it wrong can make automation a liability rather than a safeguard.

The Unattended Heater Problem: Fire Risk and Energy Waste

The fire hazard from a portable heater is a simple function of time and proximity. Most heater-related fires start the same way: the device is placed too close to furniture, fabric, or paper and then left running without oversight. The heating element, whether a resistance coil or a ceramic plate, maintains a surface temperature high enough to ignite nearby materials if given enough time.

Human presence is the natural safeguard. In an occupied room, we provide continuous, unconscious monitoring. A person will notice if a curtain drifts too close, if a pet knocks the unit over, or if the device starts to smell or sound strange. These sensory inputs trigger corrective action, like moving an object or shutting the heater down. When the room is empty, this feedback loop is severed. The heater operates in a static state while the environment around it changes. A gust of wind shifting papers or an object falling from a shelf goes undetected until it’s too late.

Time amplifies this risk. A heater running for fifteen minutes in an empty room is a minimal threat, assuming it was placed responsibly. But a heater left on for three hours, or worse, overnight, extends that window of exposure dramatically. The probability of an accident, while still low, is no longer negligible.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

Energy waste is more straightforward. Electric resistance heating is perfectly efficient at turning electricity into heat, but that efficiency is meaningless when no one is there to benefit from it. A workshop being blasted with 1,500 watts of heat is just converting money into warm, empty air. At fifteen cents per kilowatt-hour, an eight-hour period of unattended operation costs about $1.80. Over a three-month winter, that’s nearly $150 spent for nothing. Most users simply leave the heater on, accepting the risk and cost as the price of convenience. Occupancy sensing eliminates this compromise.

How Occupancy Sensing Solves the Heater Safety Equation

Occupancy sensing introduces a conditional power control that works independently of user memory or discipline. A sensor detects human presence, and a switching relay manages power to the heater based on that signal. When you’re in the room, the relay closes and power flows. When the room is vacant for a preset amount of time, the relay opens and cuts the power. The process is entirely automatic.

The primary advantage is the elimination of the unattended state. By definition, a heater under occupancy control cannot operate when the room is empty. This removes the risk of prolonged, unsupervised operation because the core condition for that risk—an active heating element without human oversight—can no longer exist. The system acts as a mechanical proxy for the watchful eye of a person.

It addresses energy waste with the same precision. It’s impossible to heat an unoccupied space when the heater’s power is tied to your presence. The system prevents the most common forms of waste, like a forgotten heater running through lunch breaks, overnight, or across a weekend. The savings aren’t marginal; they represent all the electricity that would have been consumed during periods of absence.

The system’s reliability hinges on two things: accurate detection and a properly calibrated time delay. The sensor must reliably detect presence within the target zone, avoiding false negatives that would cut power while you’re still there. Passive infrared (PIR) sensors do this by detecting motion. More advanced microwave or dual-technology sensors can identify presence even with minimal movement, like a person sitting at a workbench. The technology must match the activity in the space.

The time delay is the period between the last detected motion and the power cutoff. Too short, and the heater will constantly shut off while you’re working quietly. Too long, and you lose energy savings and reduce the safety benefit. For most workshops and studios, a delay of five to fifteen minutes is a good balance between responsiveness and tolerance for stationary work.

Occupancy Control Technologies for Portable Heaters

Implementing occupancy-based control requires a sensor to detect presence and a switch to interrupt power. Several common setups exist, each suited for different needs.

Motion-Sensing Smart Outlets

This is the simplest solution: a single plug-in device that integrates a passive infrared sensor and a relay switch. You plug the smart outlet into the wall, then plug the heater into it. The sensor watches for motion, supplying power when it detects you and cutting it after a set delay when you leave.

Installation is effortless, requiring no electrical work. The detection zone is fixed, typically a cone extending ten to twenty feet from the outlet. The main limitation is this fixed geometry; a sensor at outlet height may not effectively cover a large or irregularly shaped room. When choosing one, it’s critical to select a model rated for high-power loads. Standard smart plugs are often rated for only 10 or 12 amps, while heaters can draw up to 15. The outlet must be explicitly rated for resistive heating loads to prevent it from overheating and becoming a fire hazard itself.

Infrared Occupancy Sensors with Relay Switching

For better coverage, you can decouple the sensor from the power outlet. Ceiling- or wall-mounted occupancy sensors provide much greater placement flexibility. These sensors send a low-voltage signal to a separate relay module that switches the power to the heater’s outlet.

With this approach, a sensor can be placed in the center of a workshop for 360-degree detection, capturing movement anywhere. It also allows for more sophisticated dual-technology sensors that combine passive infrared and microwave detection, making them far more reliable for spaces where you might be stationary for long periods. The trade-off is more complex installation, as it requires running low-voltage wiring from the sensor to the relay. This setup is best for permanent workshop installations where superior performance justifies the effort.

Integrated Timer-Occupancy Hybrid Systems

Many modern smart outlets and relays offer hybrid control modes that combine occupancy sensing with a schedule. You can configure the device to enable automation only during specific hours—for example, 9 a.m. to 5 p.m. on weekdays—while preventing operation entirely at night and on weekends. This adds a powerful secondary layer of control, acting as a hard cutoff that ensures the heater won’t run after hours, even if the sensor is misconfigured.

Power Rating Realities: Matching Heaters to Sensor Outlets

A smart outlet is useless, or even dangerous, if it can’t handle the heater’s electrical load. Portable heaters are among the highest-power appliances in a home or workshop, and overloading a control device can cause it to fail, melt, or catch fire.

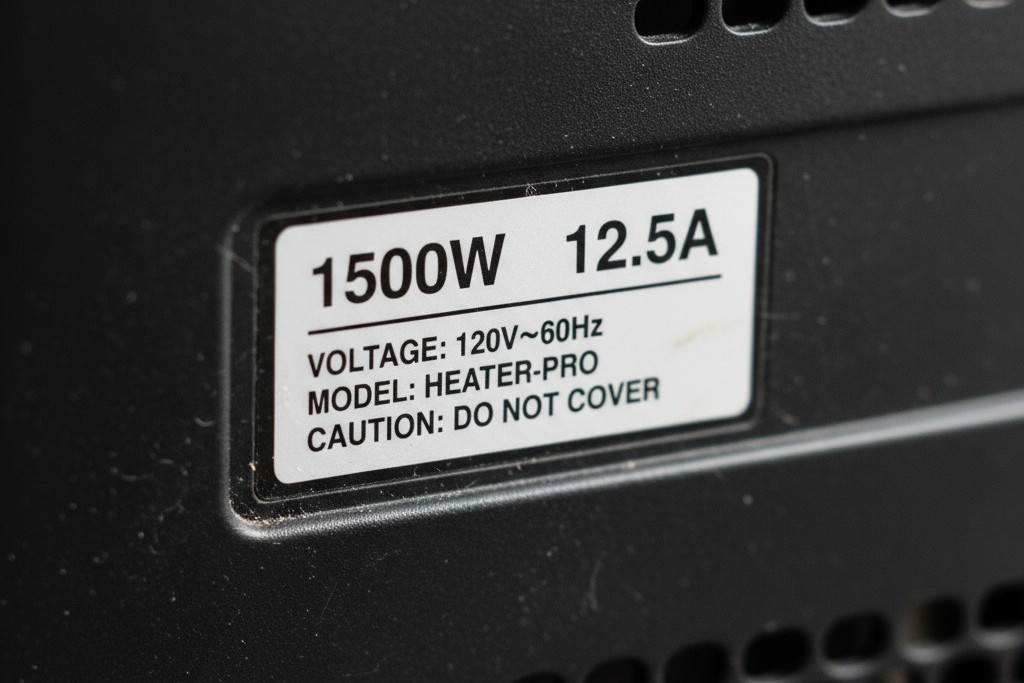

Heaters are rated in watts. To find the current they draw in amperes (amps), simply divide the wattage by the voltage (120V in the US). A 1,500-watt heater draws 12.5 amps. An 1,800-watt unit draws a full 15 amps. This is a continuous load, meaning the device pulls that current for as long as it’s running.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

Most control devices specify a maximum resistive load rating. This is the number that matters for heaters. To be safe, ensure your heater’s current draw does not exceed 90% of the outlet’s resistive load rating. That 10% margin accounts for voltage fluctuations and component tolerances. If a 1,500W heater (12.5A) is paired with a 15A-rated outlet, you’re in a safe zone. Pushing it closer to the limit is asking for trouble.

If a heater has multiple heat settings, always size your control system for the maximum possible draw. Relying on someone to remember to use only the “low” setting is not a reliable safety strategy. Assume it will be run at full power and choose a controller that can handle it.

Finally, some heaters, particularly oil-filled radiators, can create a brief “inrush” current spike on startup. This can sometimes trip a relay or cause accelerated wear. If possible, look for a smart outlet with a specified inrush tolerance, or test the specific heater-outlet combination before leaving it to operate automatically.

Implementing Occupancy Automation Across Heater Types and Spaces

The right automation strategy depends on both the heater’s technology and the space it’s in.

Radiant and Convection Heaters in Workshops

For workshops with frequent but unpredictable traffic, radiant and convection heaters are ideal candidates for automation. Both types respond quickly to power changes, reaching operating temperature in minutes and cooling down just as fast. When you walk into a cold shop, the sensor triggers the heater, and you’ll feel warmth almost immediately from a radiant unit or within five to ten minutes from a forced-air model. The shutdown is just as prompt, preventing waste.

Sensor placement here is key. If your work involves constant movement, a simple passive infrared sensor will work well. But for stationary tasks like precision machining or electronics work, you’ll need a dual-technology sensor or a longer time delay to prevent frustrating interruptions. In a cluttered shop, consider using multiple sensors wired to the same relay to eliminate dead spots behind machinery or shelving.

Oil-Filled Radiators for Studio Spaces

Oil-filled radiators have significant thermal inertia. They take 15 to 30 minutes to warm up but continue radiating heat for a long time after being shut off. This slow response can be a problem for sporadic use; you won’t feel any heat for a while after entering a cold studio. However, the slow cooldown provides a nice buffer, keeping the space warm if the sensor briefly loses detection while you’re sitting still.

Maybe You Are Interested In

A hybrid strategy works best here. Use a smart outlet’s timer to preheat the radiator 30 minutes before you typically arrive. Once you’re there, the occupancy sensor takes over, shutting the heater down when you leave for extended periods. This gives you both comfort and efficiency. Because these heaters are silent and rely on passive heat distribution, make sure your sensor covers the entire workspace, not just the area near the radiator.

Ceramic Heaters in Compact Areas

Ceramic heaters, which use a fan to circulate air over a hot ceramic element, offer the best of both worlds: they heat up in a minute or two and cool down almost instantly. This rapid response makes them perfect for occupancy control in smaller spaces like home offices or labs. A moderate time delay of five to ten minutes provides a good balance between responsiveness and tolerance for stationary work.

In dusty environments like a garage, be aware that the fan can kick up particles that may coat the sensor’s lens over time, degrading its performance. Position the sensor away from the heater’s direct airflow and clean it periodically.

When Occupancy Automation Becomes a Liability

Automation is a powerful tool, but it’s not a universal solution. In certain scenarios, it can create new hazards.

Sleeping Areas: A motion sensor will shut off a heater when you fall asleep. This is not only ineffective but potentially dangerous in freezing temperatures. Never use motion-based automation for overnight heating in a bedroom. A thermostat-controlled heater with built-in safety features is the correct tool for that job.

Highly Stationary Tasks: If your work involves sitting perfectly still for long periods (e.g., meditation, detailed painting), a basic passive infrared sensor will constantly shut off the power. Unless you invest in a high-quality dual-technology sensor, manual control is less frustrating.

High-Traffic Corridors: In a hallway or entryway, a sensor will trigger the heater for brief, pointless intervals as people pass through. This is inefficient and ineffective. Automation is for spaces people occupy, not just move through.

Heaters with Mechanical Switches: Some older heaters use physical switches that stay in the “on” position. If power is cut and then restored, they turn back on immediately. This is a critical failure risk. If your sensor or relay fails in the “on” state, the heater will run continuously and unsupervised. Only use automation with heaters that default to “off” after a power loss and require a deliberate button press to restart.

Spaces with Freeze Risk: In an uninsulated garage or shed, temperatures can plummet quickly when heating stops. If you step out for a few minutes and the automated heater shuts off, pipes or other materials could freeze. In these environments, occupancy control must be paired with a secondary thermostat that acts as a low-temperature failsafe, kicking the heater on regardless of occupancy if the temperature drops to a critical point.

Ultimately, successful automation requires a thoughtful analysis of the space, the heater, and how you use them. When the fit is wrong, disciplined manual control is always the safer choice.