In a standard office, a motion sensor has an easy job. The thermal contrast between a person and the surrounding air is significant and predictable. Place that same sensor in a walk-in freezer, and you’ve thrown it into a fundamentally hostile detection landscape. Low ambient temperatures crush the infrared signature of occupants, often to the point where passive sensors fail to see them at all. Meanwhile, compressors and refrigeration fans introduce a cacophony of mechanical vibration and electromagnetic noise, creating false triggers that undermine any potential energy savings.

The result is a system caught between two failures: either it leaves workers in the dark or it runs continuously, negating its entire purpose.

The consequences are not trivial. A sensor that fails to see a person in a freezer is an immediate safety risk. One that false-triggers on a compressor cycle wastes the very energy it was installed to conserve. For facility managers and installers, the challenge isn’t whether to use motion sensing in cold environments, but how to master the physics of detection, select the right technology, and build systems that perform reliably when conditions turn hostile.

Why Standard Motion Sensors Fail in the Cold

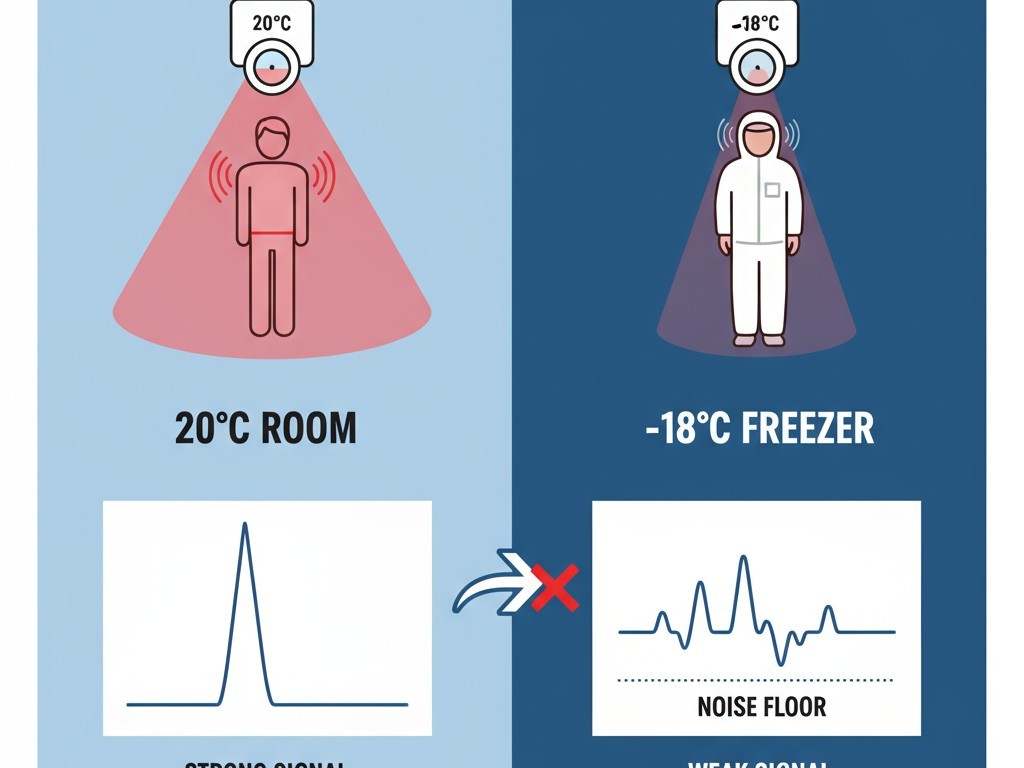

Most motion sensors, particularly the passive infrared (PIR) type that dominates commercial lighting, work by seeing heat. More accurately, they detect thermal contrast. The sensor’s pyroelectric element responds to changes in infrared energy across its field of view. When a person at 37°C moves through a 20°C room, the 17-degree differential creates a strong, clear signal.

In a walk-in freezer at -18°C, that same person presents a massive 55-degree differential. On the surface, this seems like an advantage. But the critical factor isn’t the differential; it’s the absolute infrared emission levels and the ambient noise floor. Cold air has a much lower baseline infrared signature. The human body, though still far warmer, is now buried under heavy insulated clothing, gloves, and face coverings. These layers reduce the radiating skin surface, diminishing the effective signature until it verges on the noise threshold of the detection circuitry.

The Physics of Fading Signatures

All objects emit infrared radiation as a function of their temperature. A human body at 310 Kelvin (37°C) radiates significantly more energy than a wall at 293 Kelvin (20°C). A PIR sensor doesn’t measure this temperature directly; it measures the rate of change in infrared energy as a warm body moves across the zones created by its Fresnel lens. The amplitude of this fluctuating signal must cross a certain threshold to trigger the lights. This threshold is designed to filter out slow environmental drifts from HVAC systems or sunlight.

In a cold room, the entire infrared background is suppressed. The walls, floors, and products are all near freezing. The heavily clothed human target radiates far less detectable energy from its surface. Consequently, the signal fluctuation caused by movement is weaker. When that signal falls below the sensor’s trigger threshold, detection fails. This isn’t a calibration error; it’s a fundamental limit of PIR physics in an environment that erodes thermal contrast.

How Clothing and Cold Shrink Detection Range

Sensor manufacturers specify detection range under ideal conditions: 20-25°C with an uncovered person moving across the sensor’s path. A typical ceiling-mounted PIR might reliably cover 10-12 meters in an office.

In a freezer at -18°C, with an occupant in insulated coveralls, that same sensor’s effective range can plummet to just 3-5 meters. The reduction isn’t linear. It’s a compounding effect of lower emission intensity and the signal-suppressing nature of cold-weather gear. Insulated garments are designed to trap heat, which means they also block infrared radiation. The sensor sees only the clothing’s outer surface, which is much closer to the ambient air temperature. A worker’s exposed hands or face might still radiate strongly, but they are a much smaller target than a full torso, creating a detection profile that is weak, small, and easily mistaken for background noise.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

Environmental Interference in Cold Storage

But a weak thermal signature isn’t the only problem. Cold rooms introduce active sources of interference that can trick sensors into triggering when no one is there.

Refrigeration systems generate constant mechanical vibration as compressors and fans cycle on and off. This vibration propagates through the building structure, shelves, and fixtures. Microwave and ultrasonic sensors are particularly sensitive to this. A microwave sensor detects the Doppler shift from moving objects; a vibrating fan blade or rattling shelf can create a return signal that perfectly mimics human movement, causing false triggers.

Frost and condensation are another operational challenge. When warm, humid air enters a cold room, moisture condenses on every cold surface, including the sensor’s lens. Frost buildup degrades the lens’s optical clarity, scattering incoming infrared radiation and crippling sensitivity. A thick enough layer can blind the sensor completely until it is manually cleared. This isn’t a design flaw, but an environmental reality that demands smarter sensor selection and placement.

Sensor Technologies That Work in the Freeze

The inherent failures of standard PIR sensors in cold environments demand a different approach. Fortunately, alternative technologies that don’t rely on thermal contrast can provide reliable detection, though each comes with its own trade-offs.

Microwave and Ultrasonic Alternatives

Microwave motion sensors emit a radio frequency signal (typically 5.8 GHz) and measure the Doppler shift in the reflection. Because detection is based on movement, not heat, a person in an insulated suit produces the same strong signal as someone in a t-shirt. This makes microwave sensors inherently reliable in cold environments. Their detection range doesn’t degrade with temperature. The trade-off is their lack of discrimination. Microwave energy penetrates non-metallic materials, meaning a sensor in a freezer could be triggered by movement in an adjacent hallway.

Ultrasonic sensors work similarly, but use high-frequency sound waves instead of radio waves. They are less prone to seeing through walls, but can be susceptible to air turbulence from refrigeration fans and complex echo patterns from metal shelving, which can lead to false triggers.

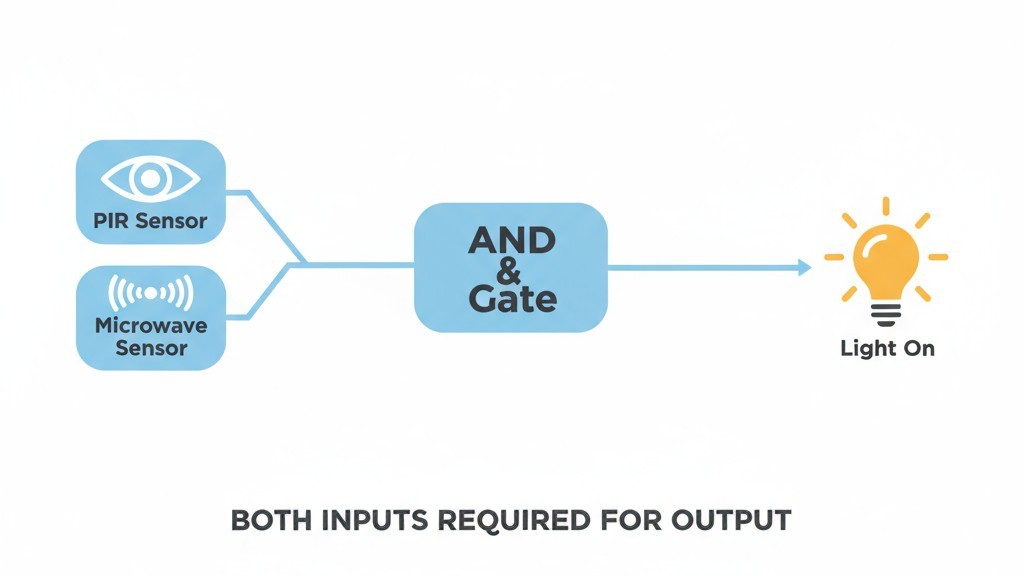

Dual-Technology: The Practical Standard

The most robust solution combines two detection methods into a single dual-technology sensor, typically PIR and microwave. The sensor’s logic requires both technologies to detect motion before it will trigger the lights.

This “AND-gate” logic is profoundly effective at eliminating false alarms. A vibrating compressor might fool the microwave detector, but the PIR, which is blind to vibration, won’t confirm the signal. A thermal draft from a defrost cycle might briefly trip the PIR, but the microwave won’t see it. The sensor remains off. Only when a person—an object with both a thermal signature and physical movement—enters the space do both technologies agree, providing a clean, reliable trigger.

For cold storage, dual-technology sensors are the practical standard. The microwave component guarantees detection despite low temperatures and heavy clothing, while the PIR component filters out the environmental noise.

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

A critical detail is ensuring the sensor itself is cold-rated. Standard electronics can fail at extreme lows. Battery-powered sensors are especially vulnerable, as lithium battery chemistry degrades rapidly below -10°C. For any freezer application, choose line-powered sensors with industrial-grade components designed for low-temperature operation.

Mounting and Coverage Strategy

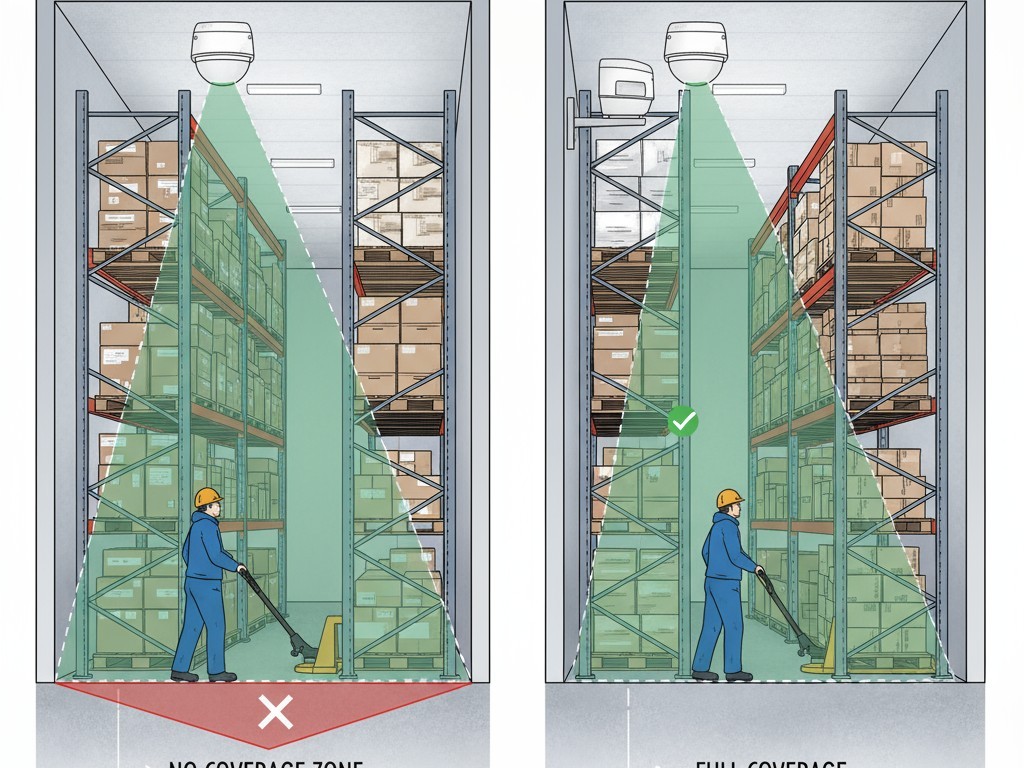

The physics of cold-room detection demand a complete rethink of standard mounting practices.

Height, Angle, and Aisle Coverage

In a typical office, a sensor mounted at 3 meters can cover a wide area. In a freezer, where a sensor’s effective range might be only 3-5 meters, the same placement creates massive coverage gaps. Lowering the mounting height to 2-2.5 meters puts the sensor closer to the target, increasing the probability of detection. This may require more sensors to cover the same area, but it’s an essential trade-off for reliability.

For facilities with long aisles, corner-mounting is often a superior strategy. Angling the sensor to look down the length of an aisle maximizes the time an occupant spends crossing detection zones, generating a stronger signal for both PIR and microwave elements.

The sensor’s Fresnel lens also plays a key role. Standard lenses create a broad, circular pattern ill-suited for long, narrow aisles. Corridor or aisle lenses reshape the detection field into an elongated oval, concentrating coverage where it’s needed most and ensuring more reliable triggering as workers move along the shelving.

Finally, be wary of mixed-temperature boundaries. A sensor near a freezer door may see clearly into the warmer loading dock while failing to detect someone deeper inside the cold room. Position sensors fully within the cold zone and rely on door contact switches, not motion sensors, for the most reliable indication of entry and exit.

Setting Timeouts and Sensitivity

In an office, a 5-minute lighting timeout is common. In a cold room, that’s a recipe for a safety hazard. Work in a freezer often involves periods of low movement—stacking boxes, reading labels, operating equipment. A short timeout risks plunging a worker on a ladder or forklift into darkness.

A baseline timeout of 10 to 15 minutes is a safer starting point. The goal is to set a delay that comfortably exceeds the longest expected pause in activity.

On a dual-tech sensor, microwave sensitivity needs careful tuning. Set it too high, and it will trigger on distant vibrations; too low, and it may miss subtle movements. Start at the midpoint and adjust only if necessary. PIR sensitivity, however, should generally be left at its maximum, as the thermal signal is already fighting to be seen.

When to Use Supplemental Controls

Even the best motion sensor has its limits. Recognizing them is key to designing a system that is both efficient and safe.

In extreme cold below -20°C, the reliability of even cold-rated electronics becomes questionable. For deep-freeze facilities, the safety risks of an unexpected lighting failure may outweigh the energy savings. In these cases, or in critical safety areas like loading docks and forklift paths, motion sensors should be supplemented or replaced entirely.

Maybe You Are Interested In

- Door Contact Switches: These provide a simple, reliable trigger. When the door opens, the lights turn on for a fixed period. This removes any dependency on detecting movement inside.

- Manual Overrides: A switch at the entrance allows workers to lock the lights on for a set time (e.g., 60 minutes) when they know they’ll be stationary for an extended period.

- Time-Based Schedules: For facilities with predictable shifts, a schedule can serve as the primary control, turning lights on during operating hours. Motion sensors then act as a secondary control to manage individual zones, providing a hybrid approach that balances savings and safety.

Installation for Long-Term Reliability

Success in cold storage depends on professional installation. Specify sensors with enclosures rated for wet or damp locations to protect against condensation from defrost cycles. Use cold-rated wire nuts and connectors that won’t become brittle and fail in the freezing temperatures.

Finally, establish a maintenance routine. Conduct quarterly walk-tests to verify coverage and response. Clean frost and condensation from sensor lenses as needed. After any significant change to the room’s layout, such as adding new shelving, recalibrate the sensors. Many dual-tech units have a learning mode that allows them to establish a new environmental baseline, ensuring they continue to filter out nuisance triggers effectively.

No sensor is perfect. The goal is to achieve reliable performance under most conditions and have robust supplemental controls for the rest. When specified correctly, installed with care, and maintained properly, motion sensors can dramatically reduce energy waste in cold storage facilities without compromising the safety and visibility that workers depend on.